Did you know that automation can boost productivity in warehouses Storage by up to 20%?

That’s right, by integrating automation in horizontal carousel storage systems, you’re not only streamlining your operations but also significantly increasing speed and accuracy.

But how does this process work? What makes these automated systems so effective and efficient?

We’re just getting started; there’s so much more to uncover about the transformative power of automation in warehouse management.

Let’s continue this conversation and explore the immense benefits that await you.

Understanding Automated Storage and Retrieval Systems

To fully appreciate the functionality and benefits of horizontal carousel systems, you first need to grasp the workings of automated storage and retrieval systems (ASRS), a revolutionary technology that blends hardware and software to automate the storing and retrieving of loads in designated storage locations.

ASRS are computer-controlled systems that efficiently place and retrieve items from specific storage spots. They use a combination of equipment and controls to handle, store, and retrieve materials with precision and speed, minimizing errors and enhancing productivity.

You may be wondering how these systems work.

Here’s a simplified explanation: ASRS consists of storage racks, input/output systems, and a computer management system. When an item arrives in your warehouse, the system scans it and determines the optimal storage location based on its size, weight, and other factors. An automated machine then places the item in the designated spot. When the item is needed, the system retrieves it using the same automated machinery, ensuring speed and accuracy.

One of the key benefits of ASRS is that it maximizes storage density by making full use of available vertical space. This results in a more efficient use of your warehouse space, and in turn, reduces costs. Moreover, ASRS improves inventory control and tracking, leading to better forecasting and order fulfillment.

Efficiency and Applications of Horizontal Carousels

Having grasped the fundamentals of automated storage and retrieval systems, let’s now explore the specifics of horizontal carousels and how they enhance efficiency and productivity in various applications. These robust systems, comprising bins moving along an oval track, are a game-changer in warehouse automation.

Horizontal carousels are designed to maximize space efficiency. By optimizing floor space, you’re able to store more in less area, thus increasing your storage density. They also excel at reducing labor requirements.

Instead of workers moving to the items, the items are brought directly to the worker at a pick station, significantly reducing travel time and improving picking efficiency.

The magic of horizontal carousels doesn’t stop at the physical system. When integrated with pick-to-light technologies and warehouse management software, the system’s efficiency skyrockets. You’ll see real-time tracking of inventory, enhanced order accuracy, and reduced order cycle times, all contributing to a more streamlined operation.

The versatility of horizontal carousels makes them a fit for various applications. From order fulfillment and buffering to returns and consolidation, these systems adapt to your business needs. Their robust design and low deployment costs make them a reliable, long-lasting solution, with a great return on investment.

The Limitations and Unique Uses of Storage Systems

While horizontal carousels and vertical lift modules offer numerous advantages, it’s crucial to understand their limitations and unique applications to ensure they’re the right fit for your warehouse operations.

For instance, horizontal carousels, while exceptional at handling smaller, lighter items, may struggle with larger, heavier goods. They’re also less suited for storing liquids due to potential spillage issues.

On the other hand, vertical lift modules can handle a wider range of item sizes and weights, including those around 25kg, making them more versatile. But keep in mind, they may require higher ceilings to operate effectively. Therefore, you should evaluate your facility’s physical layout before choosing a system.

On the flip side, vertical lift modules provide a secure and clean environment for storing special products. They’re ideal for facilities that require stringent control over inventory access and environmental conditions, such as pharmaceutical or electronics warehouses.

Maintenance, Design, and Safety Features of Horizontal Carousels

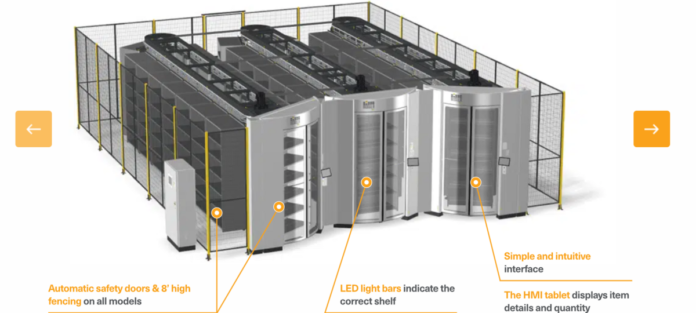

When it comes to maintaining horizontal carousels, understanding the design and safety features is essential to ensuring long-term operational efficiency and worker safety. You need to regularly inspect and service these systems to prevent breakdowns and enhance their lifespan.

The design of a horizontal carousel is quite intricate, with a focus on robustness and efficiency. The carousel consists of an oval track with bins, each having adjustable shelves to accommodate different product sizes. The system is usually integrated with pick-to-light technologies and batch stations, enhancing order-picking accuracy and speed.

Understanding this design helps you detect any anomalies during regular checks and address them promptly.

Safety features also play a crucial role. There are safety fences and control panels that protect the operator and the system. Regular inspections can help ensure these components function correctly, providing a safe and efficient work environment.

However, maintenance doesn’t stop at just regular checks. You need to keep your carousels well-lubricated, reduce load to prevent premature wear, and periodically adjust the system as per your evolving site requirements. You should also consider factors such as seismic activity and ensure your horizontal carousel is suitable for such conditions.

Conclusion

Isn’t it time you stepped up your warehouse operations?

Embracing automation in a horizontal carousel storage system promises not just increased efficiency and accuracy but also optimizes your space usage.

With such a system in place, you’ll be able to overcome operational challenges, enhance productivity, and truly elevate your warehouse management game.

So, why not harness the power of automation and redefine your warehouse operations today?