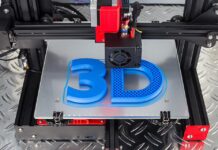

According to Research and Markets, the global additive manufacturing industry in 2021 was valued at $14.39 billion and “is projected to reach $83.56 billion by 2030 at a CAGR of 21.2% during the forecast period from 2022 to 2030.” But where will we see that growth? The healthcare, professional sports and automotive sectors will continue to reap the benefits of advancements in additive manufacturing, also referred to as 3D printing, with direct-write technology, which utilizes smaller, nanoscale, multi-materials.

The direct-write process involves a micro dispenser that applies the exact amount of materials needed to create a print on a substrate. This method allows for the creation of complex shapes using multiple materials, like metals, ceramics and composites, and can be used to produce electronic, biomedical and sensing applications. The process results in smaller, smarter objects with decreased production costs, waste reduction and quicker production times.

Healthcare advancements

Direct-write technology will benefit the healthcare industry and help with the development of medical devices, wearables and other monitoring systems. This technology dispenses inks and high-viscosity pastes, providing new usage opportunities and thereby improving clinical care. Patient health may be tracked continuously with embedded sensors, and 3D printing electronics can help researchers get to market faster.

For example, the electronic package of a smart cast includes sensors printed directly on supports that are easily embeddable in the cast structure. 3D printed circuits and sensors can allow complete integration and intelligent distribution of battery and wiring, eliminating the need for external wiring and obtrusive components. Where necessary, a multitude of sensors are able to be connected with the embedded circuit.

3D printed sensors placed directly on living tissues like bone, cartilage, tendons and skin can advance researchers’ understanding of health status and tissue response to treatment. Additionally, necessary biofeedback may be obtained to transition from developing therapeutic devices to developing theranostic devices.

Advancements in professional sports

Professional athletes across a variety of sportswear gear that incorporates sensors that monitor their heart rate, impact, altitude and more. Data provided by these nanoscale sensors can also be used to detect injury, like a concussion. The more time passes, the smarter the sensors become, thereby improving over time.

A recent article in Brainz Magazine said that “the NFL introduced a novel program in which NFL players wore mouth guards retrofitted with high-tech sensors designed to collect kinematic data, including impact speed, direction, force, location and severity.”

The NFL has also allocated millions of dollars “to improve the understanding of the biomechanics of head injuries in professional football and to create incentives for helmet manufacturers, small businesses, entrepreneurs, universities and others to develop and commercialize new and improved protective equipment, including helmets,” according to that same article.

This initiative, among many others, will help pave the way for new and smaller embedded sensors in sports gear, equipment and clothing that will ultimately benefit players and their teams.

Safer, less expensive automobiles

Whether cars are concepts, self-driving or connected, the automotive industry has developed a variety of tools by utilizing 3D printing. The utilization will continue to grow through direct-write technologies, which will enable manufacturers to optimize safety and design.

Automotive engineers and designers can quickly create prototypes of car parts and components with direct-write technologies. This speeds up the product development process and enables designers to make changes more easily, leading to faster time-to-market for new vehicle models.

Direct-write technology can produce parts with complex geometries and internal structures that can be lighter and stronger than those made via traditional manufacturing methods. This can lead to improved fuel efficiency and vehicle performance.

Traditional manufacturing often results in significant waste; materials are cut, drilled and shaped to create a final product. 3D printing significantly reduces waste, as materials are used only where needed; this also further reduces the cost of production.

Finally, supply chain flexibility is a key benefit of 3D printing; it can be used to produce small batches of parts on demand, reducing the need for large inventory stockpiles. This can help automotive companies respond more quickly to changes in demand and reduce the risk of obsolescence for slow-moving parts.

The bottom line

In addition to healthcare, sports and automotive, myriad industries will reap the benefits of utilizing direct-write technology to improve efficiency, advance research and development and address supply chain issues.