In the manufacturing sector, quality control is essential for maintaining product reliability and ensuring customer satisfaction. The process systematically works to get insights into products to make sure they meet strict standards set by both the company and regulatory bodies. Employing effective quality control maintains product consistency, thus helping to avoid the expensive process of recalling defective products.

How Quality Control Builds Consumer Trust

Think about the disappointment of purchasing a new gadget that doesn’t work. To understand the impact of quality control, consider a manufacturer committed to rigorous quality inspections. This guarantees that each product works as intended, which in turn strengthens the brand’s reputation. High-quality products garner trust and loyalty from customers, which is vital in competitive sectors where a minor fault could lead to significant erosion of customer base and revenues.

Consumer trust is the foundation upon which successful brands are built. In an era where social media amplifies both positive and negative experiences, a single instance of a faulty product can tarnish a company’s image. Implementing stringent quality control measures not only prevents such incidents but also demonstrates a company’s commitment to customer satisfaction. By consistently delivering high-quality products, manufacturers foster a loyal customer base that trusts the brand and is more likely to make repeat purchases.

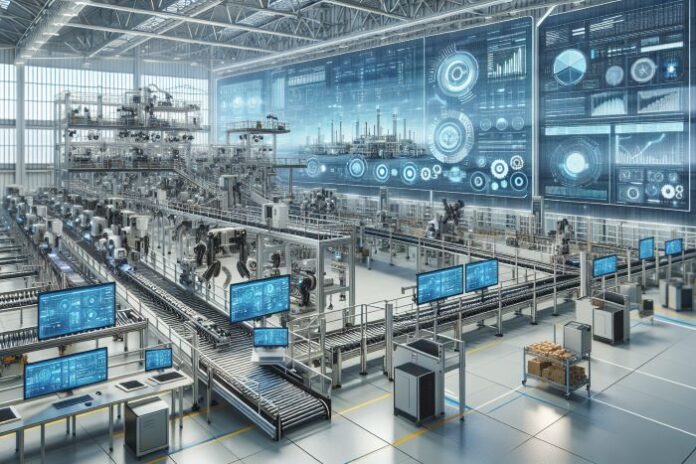

Incorporating Technology in Quality Control

Technological advancements have dramatically transformed quality control in manufacturing. Today, companies employ artificial intelligence and machine learning to predict potential flaws and address them before products are distributed. This proactive stance reduces the risk of product recalls and streamlines production processes. Additionally, real-time data monitoring offers instant quality assessments, improving manufacturing efficiency.

The integration of advanced technologies in quality control has revolutionized the manufacturing landscape. Automated inspection systems, powered by computer vision and machine learning algorithms, can detect even the most minuscule defects that might escape human eyes. These systems not only improve the accuracy of quality checks but also significantly increase the speed of inspection, thereby boosting overall productivity. The data collected by these systems can also be analyzed to identify patterns and trends, enabling manufacturers to make data-driven decisions for process improvement.

Quality Control Challenges and Innovative Responses

While establishing an effective quality control system is advantageous, it presents several challenges such as high initial costs, the need for employee training on new technologies and adjusting to rapid shifts in regulatory standards. Manufacturers can navigate these challenges through careful planning and continuous improvement. Implementing adaptable quality control systems and staying abreast of industry updates can convert these challenges into opportunities for growth and innovation.

One of the most significant challenges in implementing a robust quality control system is the resistance to change within an organization. Employees who are accustomed to traditional methods may be reluctant to adopt new technologies and processes. To overcome this challenge, manufacturers must invest in comprehensive training programs that not only teach the technical aspects of the new system but also communicate its benefits. By involving employees in the change process and addressing their concerns, companies can foster a culture of continuous improvement where quality is everyone’s responsibility.

Impact on the Adhesive Manufacturing Industry

Quality control is especially critical in specific industries like adhesive manufacturing, where products must meet precise chemical properties and performance criteria due to their use in a range of sensitive applications.

For a company like Technical Adhesives, which has provided specialized products for over 60 years, rigorous adherence to quality protocols ensures consistent performance of adhesives across various applications like packaging, bookbinding and woodworking. This commitment not only meets industry standards but also provides solutions that meet specific client needs.

Summing Up

Quality control is a cornerstone in manufacturing industries and crucial for efficiency, consumer trust and complying with legal standards. As technology evolves, the strategies for maintaining quality will also advance, balancing innovation with the reliability that customers expect.