SDSs are essential for workplace safety and compliance. But for many businesses, keeping them organized is a challenge. Traditionally SDSs are kept in paper binders or e-binders. However, problems arise when documents disappear, updates take months, or finding the correct SDS takes time. But you can resolve these issues by moving to a digital SDS management system.

In this article, we will teach you how you can move your SDS binders online.

Table of contents

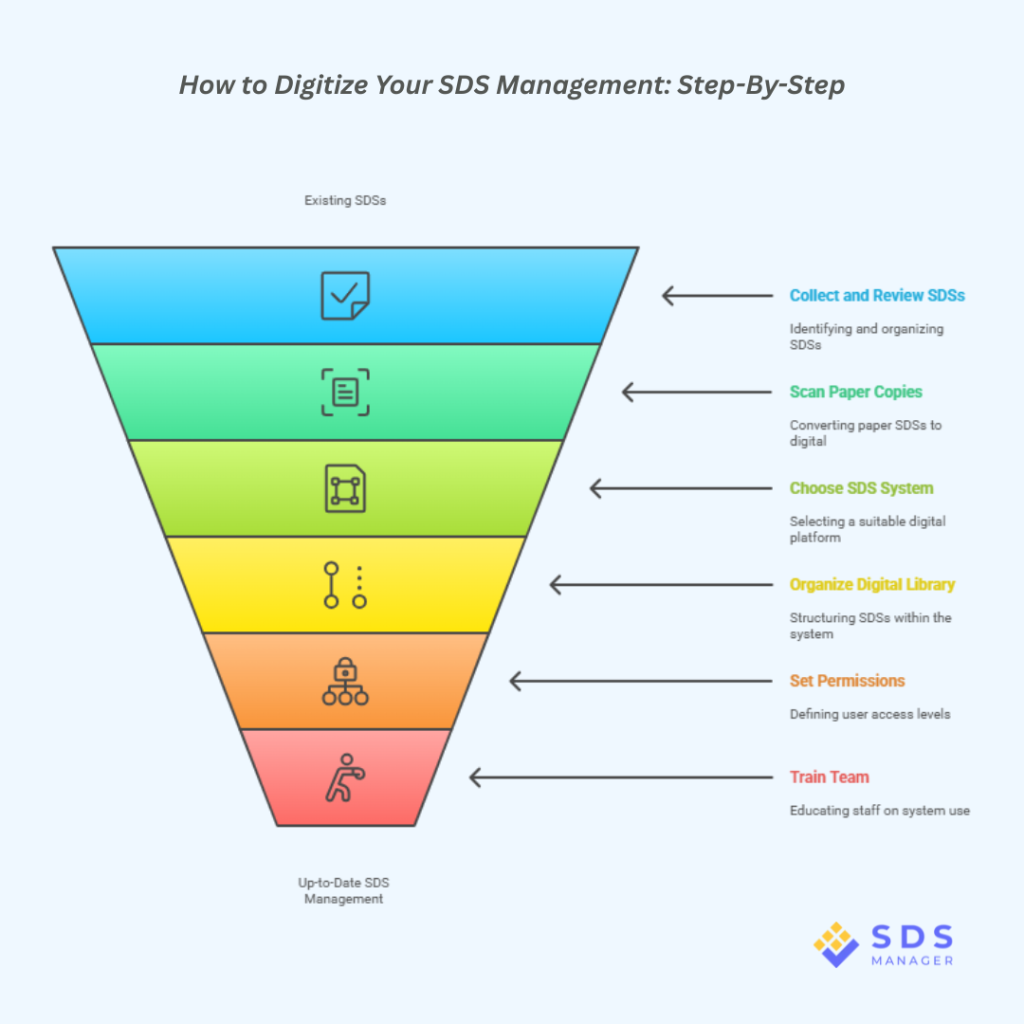

How to Digitize Your SDS Management: Step-By-Step

If you’re managing SDSs in binders, switching to a digital safety data sheet management system lets you store every SDS in one searchable database that’s always accessible and up-to-date.

Below is a clear, step-by-step process of how you can switch from binders to a digital SDS library:

Step 1: Collect and Review All Existing SDSs

Start with gathering every SDS across your company. That includes printed binders, desktop folders, or emailed copies.

Once you have everything in one place, check for duplicates or expired versions. Only keep the updated and official versions from manufacturers.

Step 2: Scan Paper Copies into Digital Files

Use a scanner to convert paper Safety Data Sheets as PDFs. When you save each file, name it clearly, like the product’s name, who makes it, and the date. This will help you find them easily later.

If your files are already in PDF format but all over the place, put them all in one folder.

Step 3: Choose a Digital SDS Management System

This is the most important step. When choosing a platform, look for these key features:

- Automatic SDS Updates: Alerts you when manufacturers release new or revised SDSs.

- Access from Anywhere: View SDSs anytime through web, mobile, or tablet.

- Smart SDS Search Tool: Find SDSs by product, CAS number, manufacturer, or hazard type.

- Offline Access: Access critical SDSs even without an internet connection.

- Multi-Site Control: Manage and update SDSs across multiple facilities from one place.

- Regulatory Compliance Support: Stay aligned with GHS and regional safety regulations.

If you choose a modern SDS tool with these features, then you don’t need to worry about manual updates or emergency access. The system built a reliable, compliant, and easy-to-use system that keeps safety information accurate and accessible for everyone.

Step 4: Organize Your Digital Library

After choosing the system that best matches your needs, start creating your SDS library in the system. You can organize your SDS library by:

- Department or work area

- Product type or hazard class

- Location or facility

Clear organization helps employees quickly locate what they need during emergencies or inspections.

Step 5: Set Permissions and User Roles

Set permissions and roles carefully. Safety managers and supervisors might edit or upload new SDSs, while most employees should have read-only access. This prevents accidental edits or deletions.

Step 6: Train Your Team

Digitization is only effective when everyone knows how to use the system. Train your staff on how to log in, find Safety Data Sheets (SDS), and understand the info they need. Short, hands-on training or guides showing the system in action work well.

When people can quickly find SDSs, your safety response gets better.

Step 7: Keep Everything Up to Date

Set up regular checks to keep your database up-to-date. Check for new chemicals, product changes, and manufacturer updates. Most SDS systems help with this by sending automatic notifications when updates happen.

Benefits of Digitizing Your SDS Management System

After digitizing your SDS management, you’ll quickly see a difference in how your workplace operates.

Faster Access and Better Organization

A digital system lets employees find the SDS they need in seconds, instead of digging through piles of paper.

Consistent Compliance

Digital systems help you follow safety regulations. You always have the latest SDS versions, and you can prove access and updates during inspections.

Improved Safety Awareness

When SDSs are easy to find and read, people are more likely to use them. This creates a stronger safety mindset and lowers the chance of chemical accidents.

Time and Cost Savings

Digital systems mean less printing, filing, and manual tracking. Over time, that saves both time and money while keeping your safety records more accurate.

Final Thoughts

You don’t have to move your Safety Data Sheets (SDS) to a digital system all at once. Start with one location or department and learn as you go. Once you’re comfortable, you can roll it out to the rest of the company.

Switching from paper binders to a digital SDS management system makes your workplace safer, more efficient, and compliant.