As additive manufacturing evolves from a niche innovation to an essential part of modern production, one of the most significant technological frontiers lies in how efficiently we can translate digital models into physical objects. Traditional slicing, the process that converts 3D models into printable layers, has long been a limiting factor in both print quality and speed. According to Forbes’ 2024 report, “AI May Be The Key To Unlocking The $14.7B 3D Printing Industry,” artificial intelligence is rapidly becoming the catalyst that drives the next wave of innovation in additive manufacturing. Adaptive slicing, enhanced by AI, represents a transformative step forward. It’s not just about faster prints or smoother surfaces; it’s about creating smarter, data-driven manufacturing systems that optimize themselves in real time.

Table of contents

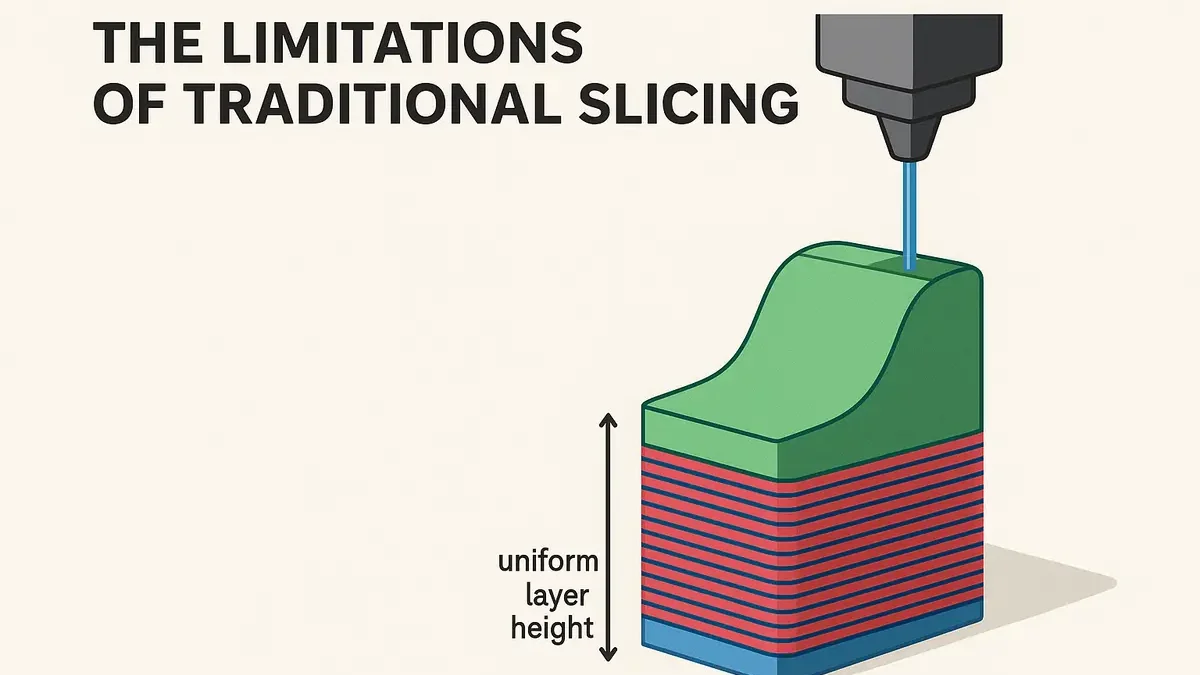

The Limitations of Traditional Slicing

In conventional 3D printing workflows, slicing software divides a digital model into uniform layers. Each layer is deposited sequentially by the printer, building the object from the bottom up. The challenge lies in balancing layer height: thinner layers produce finer detail but increase print time, while thicker layers print faster but reduce surface smoothness and geometric accuracy. Historically, this trade-off has been a fixed decision made before printing begins.

This rigidity often leads to inefficiency. For example, a complex surface detail may not require a thin layer across the entire print, only in specific localized areas. Uniform slicing, the whole model is forced to adhere to the smallest necessary layer height, wasting time and material.

What Is Adaptive Slicing?

Adaptive slicing refers to the process of automatically adjusting the thickness of layers based on the geometry of the digital model. Areas with fine details receive thinner layers for precision, while simpler or flat sections are printed with thicker layers for speed. This approach minimizes total printing time while maintaining visual and structural fidelity. Initially, adaptive slicing algorithms relied on geometric heuristics.Such as curvature analysis or slope detection to determine where and how to vary layer thickness.

However, as AI and machine learning techniques advance, adaptive slicing has become more intelligent and context-aware. Instead of relying solely on geometric calculations, AI-enhanced adaptive slicing can learn from previous prints, analyze part performance, and even anticipate print behavior based on material characteristics and environmental conditions. This transition from rule-based logic to data-driven intelligence marks a pivotal change in how software manages the 3D printing process.

How AI Is Transforming Slicing Algorithms

AI’s role in adaptive slicing is primarily centered around predictive optimization. Using data from prior print jobs, such as print speed, layer adhesion, thermal distribution, and material behavior, machine learning models can predict the optimal layer structure for new prints. Neural networks can detect patterns in geometry that correlate with specific print challenges, such as warping or under-extrusion, and proactively adjust layer heights, extrusion rates, and path planning.

One emerging trend involves reinforcement learning systems that treat the slicing process as a feedback loop. These systems receive real-time sensor data from the printer and adjust parameters dynamically to maintain quality and efficiency. For instance, if the AI detects minor deviations in temperature or extrusion flow, it can recalibrate slicing parameters mid-print to compensate. This capability effectively allows printers to “learn” from each print, improving both consistency and throughput over time.

Integration with Modern 3D Printing Systems

The success of adaptive slicing algorithms depends on seamless integration between software and hardware. Advanced printers today come equipped with onboard computing capabilities that enable real-time parameter updates. This integration is particularly evident in large-format and multi-material 3D printers, where adaptive slicing’s benefits become even more pronounced.

Large-format 3D printers handle massive builds where time and precision are both critical. The ability to adapt layer height across vast surfaces can save hours or even days in production. In this context, printers like the Best Large Format 3D Printer Overall: Bambu Lab H2S demonstrate how intelligent software can harness adaptive slicing to manage large-scale geometries efficiently. The printer’s high-resolution control system works in tandem with AI slicing algorithms to balance print speed and detail dynamically.

Similarly, adaptive slicing has transformative implications for multi-material printing. When a printer uses multiple extruders to combine different materials, such as rigid and flexible polymers, the slicing strategy must account for varying thermal and mechanical behaviors. In such cases, the Dual-Extruder 3D Printer for Multi-Material Projects: Bambu Lab H2D exemplifies the practical application of adaptive AI slicing. Its software-driven calibration ensures that transitions between materials are smooth and precise, using AI to determine the optimal boundary layers and extrusion rates in real time. The result is not only improved surface finish but also better structural integrity across dissimilar materials.

The Software Architecture Behind Adaptive Slicing

At a software engineering level, implementing AI-driven adaptive slicing involves multiple layers of computation. The slicing pipeline typically includes:

- Geometry Analysis: The model is parsed into topological data, identifying curves, slopes, and feature density.

- Feature Extraction: AI models analyze patterns in geometry and map them to previous printing data.

- Layer Parameterization: The algorithm determines variable layer heights, infill densities, and extrusion parameters.

- Simulation and Validation: The slicing engine simulates print paths, checking for potential print failures or structural weaknesses.

- Feedback Integration: Real-time sensor data from previous prints is used to fine-tune the algorithm for future jobs.

Developers often use frameworks like TensorFlow or PyTorch to build the learning components of adaptive slicing systems. These models are trained on datasets containing geometric features, print metrics, and post-processing inspection results. Over time, they improve their predictive accuracy, reducing the need for manual slicing adjustments. This smart software must also maintain compatibility with G-code standards while allowing for dynamic layer transitions, a challenging feat in firmware design.

Broader Implications for Additive Manufacturing

AI-driven adaptive slicing doesn’t just improve print quality; it changes the economics of 3D printing. By reducing material waste, print time, and error rates, manufacturers can achieve faster prototyping cycles and lower operational costs. For industries like aerospace, automotive, and healthcare, where precision and repeatability are paramount. Adaptive slicing is an enabling technology that bridges the gap between experimental printing and scalable production.

Moreover, adaptive slicing sets the stage for fully autonomous 3D printing ecosystems. As AI slicing algorithms mature, they will integrate with cloud-based platforms, allowing printers to share learning models across networks.

Conclusion

Adaptive slicing, powered by AI, represents the next leap in 3D printing intelligence. By merging data analytics, geometry processing, and real-time optimization, it turns a traditionally static process into a self-improving system. The results are more brilliant, faster, and more precise prints achieved with less manual intervention. As printers like the Bambu Lab H2S and Bambu Lab H2D showcase, the fusion of adaptive software and advanced hardware is driving additive manufacturing toward a new era of efficiency and autonomy.