3D printing is rapidly evolving from a creative hobby into a cutting-edge digital manufacturing technology. Today, it’s no longer just about machines shaping plastic, it’s about software transforming ideas into precise, functional objects. The future of 3D printing depends on one thing: how well software and materials work together to bring innovation to life. Recent studies explore how advances in materials science and computational modeling are driving the evolution of next-generation additive manufacturing processes.

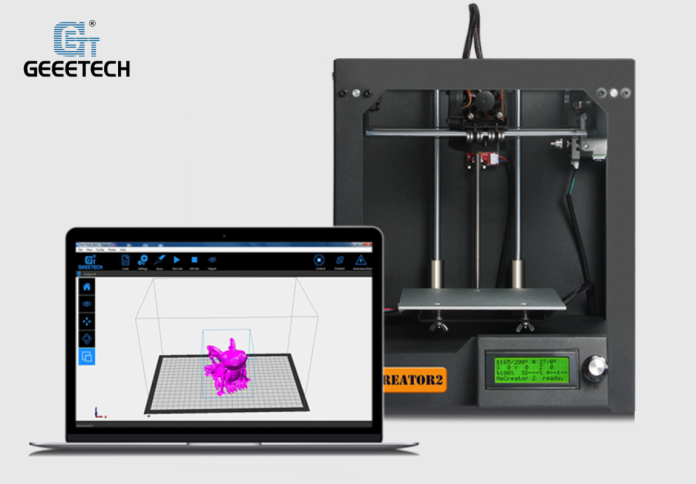

At the center of this transformation are two key players: 3D printing software like Geeetech’s EasyPrint, the newly launched 3D printing software under the brand name Geeetech, and high-quality materials such as 3D printer filament. Together, they form the foundation for smarter, faster, and more creative design experiences.

Table of contents

Bridging Design and Reality with Smart Software

In the early days, 3D printing required a lot of manual calibration and technical know-how. Now, with intelligent software like EasyPrint by Geeetech, users can streamline the entire process from preparing digital models to executing precise prints. EasyPrint provides a user-friendly interface that allows beginners, designers, and engineers to visualize, adjust, and slice models seamlessly before printing.

The real strength of this software lies in its optimization capabilities. It analyzes print parameters like temperature, layer thickness, and speed, helping users achieve consistent results without wasted material. For professionals, EasyPrint also enables remote management and real-time monitoring, ensuring every print maintains high accuracy and quality.

This level of control not only improves print efficiency but also makes 3D printing more accessible to everyone, removing the steep learning curve that once limited innovation.

Why the Right Filament Still Matters

Even the most innovative software can’t perform miracles without the right material. That’s where high-quality filaments come in. Choosing the proper filament affects every aspect of your design, from surface finish to strength and flexibility.

If you’re working on a quick prototype or a simple decorative piece, a basic material might be enough. But if your project demands durability, heat resistance, or smooth detailing, you’ll need more specialized materials. That’s why Geeetech offers a wide selection of reliable filaments, each tailored to different performance needs. Their PLA filament, for instance, is made from eco-friendly sources like cornstarch or sugarcane and is known for its ease of use and clean surface finish, making it a go-to choice for designers and students alike.

Advanced users may also explore options like PETG for strength and flexibility, or ABS for industrial-grade endurance. With the right balance between software settings and filament selection, every print can achieve near-professional precision.

Software and Material Synergy: The Future of 3D Printing

The real innovation in 3D printing lies in the synergy between innovative software and high-performance materials. Software like EasyPrint doesn’t just control the printer; it communicates directly with the hardware and the material to optimize performance. By automatically adjusting temperature, extrusion rate, and support structures, it ensures every layer aligns perfectly.

Imagine designing a complex architectural model or a custom mechanical part. The software translates every curve, hole, and edge into accurate print paths, while the filament provides the strength and texture to make it real. Together, they turn digital imagination into tangible reality.

As technology progresses, we’re seeing more intelligent algorithms that predict material behavior, auto-correct printing errors, and even recommend the best filament type for specific designs. This seamless integration of AI-driven software and advanced materials will redefine how we create everything from household tools to industrial components.

Sustainable and Smarter Printing Ahead

Innovation in 3D printing isn’t just about precision; it’s also about responsibility. Geeetech’s continuous development in biodegradable filaments and energy-efficient software design shows a commitment to sustainability. With PLA and other bio-based materials gaining traction, 3D printing is stepping toward a greener future without compromising quality.

Soon, users may see cloud-based software platforms that suggest optimal print settings based on project type, or AI-assisted tools that automatically detect printing issues mid-process. These advancements point to a more intelligent, connected, and eco-conscious 3D printing ecosystem.

Conclusion

The next era of 3D printing will be shaped not only by powerful machines but by the perfect collaboration between software and materials. Tools like EasyPrint and Geeetech simplify complex workflows, while Geeetech’s wide range of filaments ensures precision and quality in every print.

Choosing the right 3D printer filament isn’t just about compatibility; it’s about unlocking creative potential through innovative technology. With software guiding precision and materials fueling innovation, the future of 3D printing is more dynamic, sustainable, and limitless than ever before.