For many years, CNC machining has been known for what happens on the shop floor: cutting tools, spindles, fixtures, and skilled operators turning designs into physical products. But the most critical change in CNC machining today is not occurring on the machines. It is happening in software.

Quietly, modern CNC machining platforms are building what might best be called an invisible factory: a digital manufacturing ecosystem in which software orchestrates the intake of design, quoting, production planning, quality assurance, and delivery, often across geographies and multiple facilities. As Forbes has noted, digital factories, where software manages quoting, scheduling, and production, are no longer a niche concept but a core evolution in manufacturing strategy. CNC machining platforms represent one of the most straightforward and most practical expressions of this shift.

Table of contents

- CNC Machines Are No Longer the Center of the System

- The Software Stack Behind the Invisible Factory

- Software as the New Production Manager

- Quality Control Moves Upstream

- From Local Job Shops to Global Manufacturing Networks

- The Strategic Shift: Manufacturing as Software

- Conclusion: Seeing What Was Always There

CNC Machines Are No Longer the Center of the System

Traditional CNC operations are machine-centric. Planning for capacity, scheduling, quotation, and quality control are frequently handled manually or in siloed systems. Machines do the work, but between design and delivery, human skills are woven in to fill the gaps.

Software-driven CNC machines turn that model upside-down. Data and workflows, not machines, are the organizing principle of the network. Machines turn into the endpoints of a vastly larger digital system that consolidates complexity at scale.

In the new model, the true competitive advantage isn’t spindle speed or axis count; it’s in how quickly you can flow information from customer intent to the finished part.

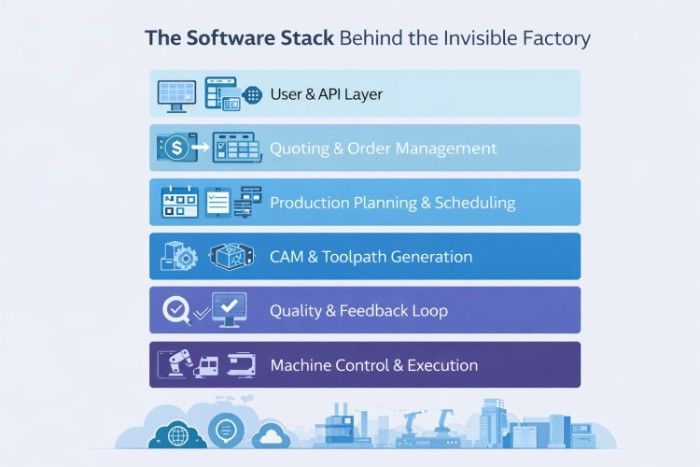

The Software Stack Behind the Invisible Factory

At the heart of CNC machining platforms is a multi-layered software stack designed to automate and standardize once manual processes.

1. Digital Design Intake and File Intelligence

Modern platforms use software to automatically analyze CAD files. Geometry, tolerances, materials, and manufacturability constraints can be interpreted by algorithms before a human ever reviews the job. This reduces errors early in the process and accelerates decision-making.

2. Automated Quoting and Cost Modeling

Quoting has long been among the slowest and most inconsistent parts of a machining production run on a CNC machine. Driven by software, platforms can provide faster, more consistent pricing based on historical data, machining rules, and real-time capacity. This doesn’t just speed up the process; it also lowers the risk of underquoting or overruns.

3. Intelligent Supplier Matching and Capacity Allocation

Rather than relying on a single shop’s capabilities, CNC platforms use software to match jobs with the most suitable manufacturing partners based on machine type, material expertise, lead time, and quality history. This is where the invisible factory truly takes shape: production is distributed, but coordination is centralized.

This is the layer where CNC Machining platforms like Haizol operate as orchestration engines, connecting demand with a global network of manufacturing capacity through software rather than physical ownership of machines.

Software as the New Production Manager

Scheduling, machine availability, tooling, and delivery dates are traditionally juggled manually by production managers. This is also gradually being taken over by software-led CNC machining platforms.

Algorithms might automatically adjust schedules when slowdowns occur, reassign work to different suppliers, and let workers see how their jobs are progressing in real time. It isn’t easy to achieve this level of coordination using spreadsheets, emails, and phone calls.

The result is greater resilience. The platforms that lash those machines together, in the form of software-driven CNC platforms like Xometry’s, have developed a new utility during this crisis: When supply chains are upended and demand spikes without warning, a coordinated network of software can adjust faster than any single shop toiling away on its own.

Quality Control Moves Upstream

In CNC machining, part quality has traditionally been reactive, with inspection performed after parts are made. Software-led CNC machining platforms move quality control upstream.

Because design rules, tolerance checks, and process standards are built into the platform itself, many quality concerns are addressed before production. Information from previous jobs is continuously fed back into the system to enhance decision-making and minimise rework. This data-centric approach allows quality to be managed at the system level rather than relying solely on individual operators or inspectors.

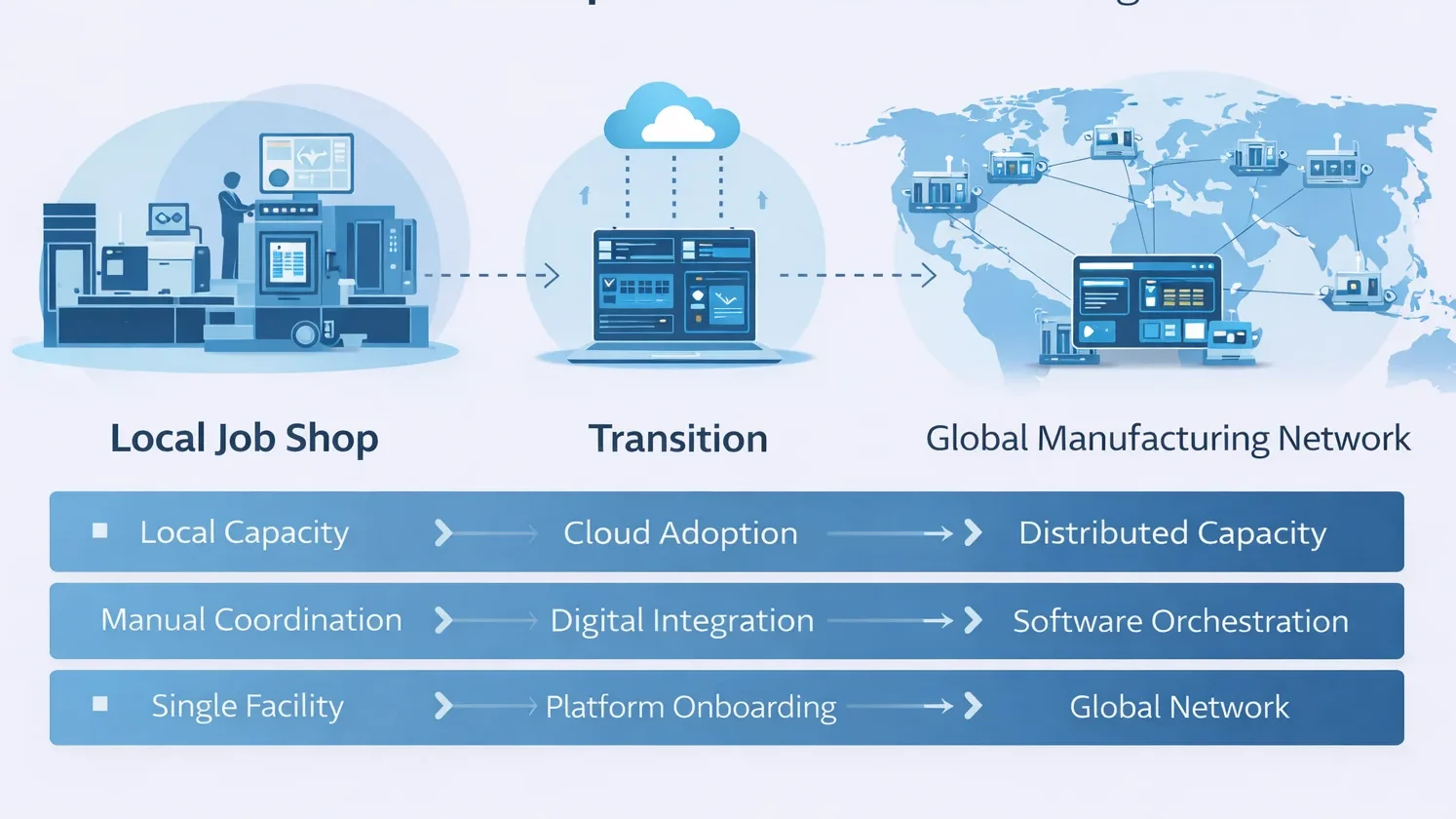

From Local Job Shops to Global Manufacturing Networks

One of the most fundamental effects of embracing CNC/cam platforms is their re-conception of scale. Scale in CNC used to mean more machines, more floor space, and more labor. Software changes that equation.

Platforms can scale by bringing on new manufacturing partners , spanning geographies, and streamlining workflows without owning a single machine. This changes CNC machining from a local to a global distributed manufacturing network.

For clients, it means access to deeper resources, more responsive service, and greater overall nimbleness. For makers, that means access to demand they might not otherwise have a way to tap into.

The Strategic Shift: Manufacturing as Software

The invisible factory represents a broader shift toward manufacturing as software. Physical machining remains essential, but it is increasingly commoditized. What differentiates modern CNC platforms is their intelligent management of information, workflows, and relationships.

As AI, cloud computing, and data analytics mature, CNC machining platforms will continue to evolve, predicting lead times more accurately, optimizing designs automatically, and enabling tighter integration between engineering and production.

In this future, the most valuable assets are not just machines, but the software systems that connect them into a cohesive, intelligent whole.

Conclusion: Seeing What Was Always There

The factory was never just a physical location; it was always a complex of coordination, decision-making, and execution. Software-driven CNC machining platforms help you see the system and make it more scalable and efficient.

As the sector progresses, knowledge of the invisible factory will be vital for any company hoping to remain competitive. CNC machining isn’t just about what happens at the machine; it is about the software that makes everything else go.