Enterprise resource planning (ERP) began as little more than a back-office ledger. Today, it runs the nerve center of a smart factory—connecting production lines, supply chains, and finance in one live system. When you choose a platform, you also choose the manufacturing ERP consulting team that threads it into daily operations, influencing everything from material flow to profit margins.

Momentum is clear: an IndustryWeek 2025 survey found that 94 percent of large manufacturers plan to invest in a new ERP within two years, and 9 out of 10 favor cloud deployment. U.S. CHIPS Act incentives and reshoring trends add extra urgency.

Speed now hinges on expert guidance. Panorama Consulting reports that cloud ERP projects led by seasoned consultants finish in about nine months and reach ROI targets far more often than DIY efforts. The gap can make or break a digital strategy.

That’s why we created this guide. We profile the ten leading ERP platforms and their consulting ecosystems, map each one to the capabilities manufacturers need most, and give you a clear path to a confident shortlist. Let’s find the system–and-partner combo that will carry your operations into 2026 and beyond.

Key Takeaways

- Manufacturers increasingly rely on cloud-based solutions for manufacturing ERP consulting, driven by speed and ROI.

- Specialized consulting teams enhance ERP implementations by aligning systems with actual workflows on the shop floor.

- Our guide reviews ten leading ERP platforms and their consulting ecosystems to streamline vendor selection for manufacturers.

- Key evaluation criteria include manufacturing functionality, supply-chain strength, analytics, and implementation track record.

- A disciplined approach to shortlisting vendors can lead to successful ERP implementations that produce lasting value.

Table of contents

- Key Trends Shaping Manufacturing ERP Consulting Selection for 2024–2026

- Why Specialized Manufacturing ERP Consulting Is Critical for Manufacturers

- Top Manufacturing ERP Consulting Solutions and Services For 2026

- MCA Connect + Microsoft Dynamics 365: Unified Operations for Discrete Manufacturers

- SAP S/4HANA + Global System Integrators: Enterprise Depth for Complex Manufacturers

- Oracle Fusion Cloud ERP: Finance-To-Factory Visibility with Supply-Chain Strength

- Oracle Netsuite: Cloud Suite for High-Growth Manufacturers

- Infor CloudSuite Industrial and M3: Industry-Specific Depth Without Tier-One Overhead

- IFS Cloud: Agile Control for Asset-Intensive and Project-Based Manufacturers

- Epicor Kinetic: The Mid-Market Workhorse Built for the Shop Floor

- QAD Adaptive ERP: Precision Fit for Automotive and Life-Sciences Supply Chains

- Rockwell Plex Systems: Real-Time ERP and MES in a Single Cloud

- SYSPRO: Scalable Control for Discrete and Mixed-Mode Producers

- Comparison Matrix: How The Leaders for Manufacturing ERP Consulting Stack Up

- Conclusion and Next Steps

Key Trends Shaping Manufacturing ERP Consulting Selection for 2024–2026

Cloud deployment is now the default for ERP, with most new rollouts on SaaS platforms that reduce average go-live timelines from over a year to about nine months. For manufacturers facing cost and capacity pressures, this speed accelerates ROI. Embedded intelligence is also becoming standard: shop-floor sensors, AI forecasting, and self-healing supply-chain algorithms are moving from pilot projects to daily operations, with 63 percent of manufacturers citing AI as a top buying criterion. Predictive maintenance and demand-planning models can often deliver measurable returns within a year.

Supply-chain resilience remains a top priority, as pandemic disruptions, geopolitical risk, and sustainability mandates drive demand for real-time visibility from raw materials to finished goods. The market is consolidating, with four vendors holding most global share and appearing in IDC MarketScape’s Leader quadrant. Choosing an ERP today means evaluating not just software functionality, but the partner ecosystem that will continue to support, innovate, and scale with your operations over the next five years.

Why Specialized Manufacturing ERP Consulting Is Critical for Manufacturers

Manufacturing ERP implementations succeed or fail on the shop floor, not in finance templates. Standard ERP configurations rarely account for the realities of complex bills of materials, shifting batch formulas, or tightly sequenced production lines. Specialized manufacturing consultants bridge that gap by mapping real workflows into the system, aligning ERP configuration with how work actually gets done. Their experience reduces trial and error, supports engineer-to-order and mixed-mode production, and keeps implementations aligned with proven cloud ERP timelines.

The value of specialized consulting continues well after go-live. Experienced partners provide structured data migration, role-based training, and ongoing optimization frameworks that accelerate adoption and stabilize performance. With the right guidance, teams spend less time managing workarounds and more time improving throughput, turning ERP solutions from a basic system of record into a lasting operational advantage.

Our Evaluation Criteria for ERP Solutions and Consulting Services

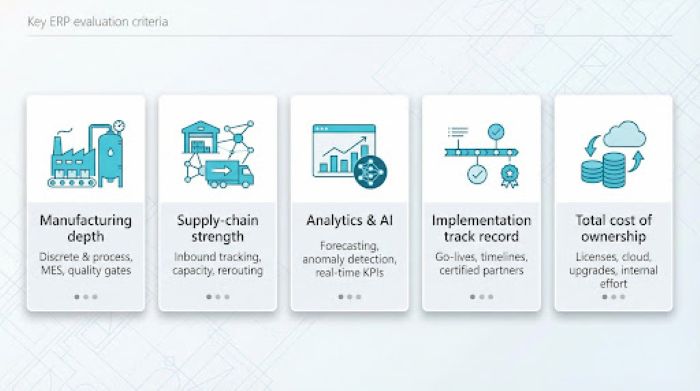

Before we rank any platform for manufacturing ERP consulting, we build a scorecard that mirrors the questions you will ask during a vendor demo.

- Depth of manufacturing functionality. Supports discrete and process manufacturing, integrates with MES, and enforces quality controls without heavy customization.

- Supply-chain strength. Tracks materials, models capacity, and adapts quickly to disruptions to protect on-time delivery.

- Analytics and AI. Delivers embedded forecasting, anomaly detection, and operational insights in real time, not just at period close.

- Implementation track record. Proven success with live manufacturing deployments, realistic timelines, and experienced, certified partners.

- Total cost of ownership. Accounts for licensing, cloud infrastructure, upgrades, internal effort, support, and long-term scalability for side-by-side comparison

Top Manufacturing ERP Consulting Solutions and Services For 2026

We sifted through analyst quadrants, customer case studies, and live factory tours to assemble a clear short-list. Each solution pairs solid software with a consulting ecosystem that knows how to make it perform on the shop floor.

Below you will find the first of our 10 profiles. We will release the remaining nine in the next installments so you can digest each option without information overload.

MCA Connect + Microsoft Dynamics 365: Unified Operations for Discrete Manufacturers

MCA Connect is a long-time Microsoft partner focused solely on manufacturing; with more than 1,000 manufacturing ERP implementation projects delivered across 50+ countries, its consultants arrive already fluent in mixed-mode production, IoT data flows, and the art of taming a multi-level bill of materials.

They use Microsoft Dynamics 365 Supply Chain Management and Finance as the backbone. The cloud suite links engineering change orders, procurement, and shop-floor execution in real time, so planners and operators work from the same source of truth. MCA’s proprietary Connected Blueprint accelerates discovery workshops, trims customization, and keeps most projects inside the sub-12-month window that agile manufacturers expect.

Customers report faster quoting, tighter inventory turns, and the welcome disappearance of spreadsheet firefights. Because Dynamics 365 sits in Microsoft’s evergreen cloud, new AI copilots for demand forecasting or quality anomaly detection arrive automatically, protecting the investment.

MCA Connect and Microsoft therefore take the first spot on our list of manufacturing ERP consulting. They blend global platform scale with boutique manufacturing expertise, an appealing mix for mid-sized and enterprise discrete producers aiming to modernize without the weight of a tier-one monolith.

SAP S/4HANA + Global System Integrators: Enterprise Depth for Complex Manufacturers

SAP S/4HANA is a familiar presence on the plant floor, offering end-to-end coverage from finance through digital manufacturing on a real-time, in-memory platform. Most enterprises pair the software with global system integrators such as Deloitte, Accenture, or Capgemini, whose industry best-practice templates for sectors like automotive, chemicals, and mill products accelerate process design and change management.

S/4HANA excels in complex, multi-plant environments, supporting discrete, process, and mixed-mode manufacturing within a single system while balancing global capacity and feeding live shop-floor data into predictive planning. Implementation requires significant effort and investment, but organizations that commit gain a robust operating platform designed for global scale and supported by the largest ERP partner ecosystem in the market.

Oracle Fusion Cloud ERP: Finance-To-Factory Visibility with Supply-Chain Strength

Oracle built its reputation on strong financials and project accounting, then extended its cloud platform with a modern supply-chain suite. Fusion Cloud ERP gives controllers, planners, and plant managers a unified view of demand and inventory, enabling faster, more coordinated decision-making across the organization. Embedded AI flags slow-moving parts, suggests alternative suppliers, and highlights maintenance risks before production is affected.

Implementations are typically led by global consultancies like Infosys or PwC, using pre-configured industry accelerators to keep scope manageable and timelines within nine to twelve months. Fusion Cloud ERP is particularly suited for plants already using Oracle databases or seeking deep, native analytics without add-ons, offering a balance of comprehensive functionality and agile user experience for hybrid manufacturing and distribution networks.

Oracle Netsuite: Cloud Suite for High-Growth Manufacturers

NetSuite was born in the browser long before cloud became mainstream. That heritage shows in its deployment speed. Many mid-sized manufacturers replace a patchwork of QuickBooks, spreadsheets, and siloed scheduling tools in six to nine months, then scale globally without new servers or version upgrades.

The manufacturing edition wraps ERP, CRM, and e-commerce into one database. Planners see demand spikes roll straight into MRP, while customer-service teams track orders down to the work-order level. Multi-currency and multi-language support come standard, so an electronics start-up can open an Asian contract plant and still close consolidated books in days, not weeks.

Implementation partners rely on NetSuite’s SuiteSuccess templates. These pre-configured roles, dashboards, and KPIs slice weeks off discovery workshops and lock scope early. That discipline matters when resources are tight and board timelines loom.

If you need strong supply-chain planning and live dashboards but lack the IT headcount for a tier-one giant, NetSuite provides a clear route to world-class control.

Infor CloudSuite Industrial and M3: Industry-Specific Depth Without Tier-One Overhead

Infor offers industry-specific cloud solutions rather than a single monolithic platform. CloudSuite Industrial (SyteLine) serves discrete manufacturers, while M3 targets process environments with batch traceability and recipe management. Both run on Infor OS, providing embedded AI, Birst analytics, and IoT integration for real-time production visibility.

Implementation is handled by Infor teams or specialized partners, reducing heavy customization. Preconfigured functionality keeps projects lean and predictable, delivering strong manufacturing depth at mid-market cost—ideal for firms that find tier-one ERP too large but need precise industry fit.

IFS Cloud: Agile Control for Asset-Intensive and Project-Based Manufacturers

IFS Cloud combines ERP, enterprise asset management, and field service in one platform, designed for aerospace, industrial machinery, and automotive suppliers. Engineers use configure-to-order workflows, project accountants track costs over time, and plant managers rely on built-in quality and document controls.

Implementations can be direct or via certified partners, with preconfigured dashboards and workflows enabling many teams to reach first go-live in under a year. Phased expansion into service management or IoT analytics is seamless, unifying design, production, and service into a single, continuously improving system.

Epicor Kinetic: The Mid-Market Workhorse Built for the Shop Floor

Epicor Kinetic preserves decades of shop-floor experience while adding a modern interface and Azure-powered IoT feeds for real-time production dashboards. Job shops benefit from fast quoting and job costing, while make-to-order manufacturers rely on advanced scheduling to maximize throughput.

Implementations are typically phased, starting with core modules and expanding over time, which controls cost and change management. Epicor Kinetic delivers enterprise-level functionality without unnecessary complexity, making it ideal for mid-market manufacturers.

QAD Adaptive ERP: Precision Fit for Automotive and Life-Sciences Supply Chains

QAD built its reputation in highly regulated, time-sensitive industries, and Adaptive ERP extends that expertise into a flexible cloud platform. It handles regional compliance and fluctuating demand while maintaining precision and operational control.

On the shop floor, QAD synchronizes production schedules through OEM-driven EDI and provides end-to-end traceability via barcode scanning, batch genealogy, and electronic signatures. Consulting teams use micro-vertical templates to accelerate implementation, helping many mid-sized manufacturers reach first-plant go-live in nine months and scale efficiently.

Rockwell Plex Systems: Real-Time ERP and MES in a Single Cloud

Plex combines ERP with a full manufacturing execution system, capturing every machine cycle, quality check, and inventory move in real time. Operators, supervisors, and quality teams gain instant visibility, and maintenance actions trigger automatically when sensor data drifts out of tolerance.

Since Rockwell Automation’s acquisition, Plex has expanded IIoT and analytics capabilities. Industry-specific blueprints enable fast go-live, often in six months, with multi-site alignment on a single cloud instance. Plex provides a unified source of truth from raw material to finished product for manufacturers seeking granular shop-floor control.

SYSPRO: Scalable Control for Discrete and Mixed-Mode Producers

SYSPRO serves mid-sized manufacturers and distributors needing full ERP without heavy administrative overhead. Core finance and production modules can be expanded with advanced planning, MES, or automation as operations grow, all within the same system.

Manufacturers value SYSPRO’s granular inventory control, multi-warehouse management, and support for discrete, batch, and mixed-mode production. Regional partners deliver implementations efficiently, with many companies reaching go-live in under nine months and realizing cost reductions within the first year.

Comparison Matrix: How The Leaders for Manufacturing ERP Consulting Stack Up

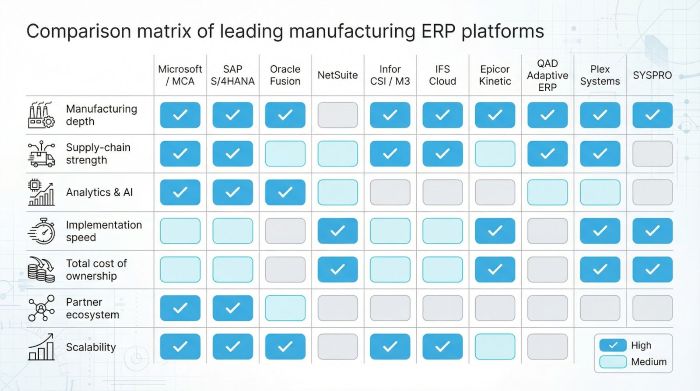

To bring the big picture into focus, we scored each platform on the criteria listed earlier: manufacturing depth, supply-chain strength, analytics and AI, implementation speed, total cost of ownership, partner ecosystem, and scalability.

A quick glance shows SAP and Microsoft/MCA earning top marks for breadth of functionality and partner reach, while NetSuite and Plex lead on speed to value and lower ongoing costs. Infor and IFS land in the sweet spot, offering strong industry fit without tier-one overhead. QAD leads on regulatory compliance for auto and life sciences. Epicor and SYSPRO shine for mid-market flexibility, and Oracle Fusion stands out for finance-to-factory analytics.

Use the matrix as a filter, not a final verdict. Focus on the two or three columns that map to your biggest pain points, then shortlist the vendors with “High” in those rows. This disciplined approach turns a crowded market into a focused demo plan.

Conclusion and Next Steps

Modern ERP is no longer just a record keeper. When paired with the right consulting partner, it becomes the nervous system of a smart factory, sensing, learning, and guiding every decision from raw material to revenue.

We have outlined the 10 strongest paths forward, mapped their strengths, and shown where each excels. Now it is your move. Gather a cross-functional team, define the three or four capabilities most likely to move your KPI dial, and line up demos with the vendors that scored “High” in those columns.

Bring real data, invite the consultant who will lead the project, and set measurable success metrics up front. Follow this playbook, and your next manufacturing ERP consulting will deliver value long after the go-live banners come down.