Automation persists in transforming machine functionality throughout virtually all industries. From high-precision production setups to advanced healthcare devices, regulated mechanical displacement stands at the heart of progress. Numerous specialists examining linear motion examples soon realize that steady, scripted thrusting and pulling power facilitates dependable alignment in settings demanding exactness. Central to such setups are linear motion actuators, small units engineered to transform electric power into regulated straight-line displacement.

In contrast to fluid-based or air-driven setups, electrical actuation delivers easier incorporation, softer functioning, and adjustable management. These benefits account for the ongoing growth of linear displacement tech into fields emphasizing productivity, security, and smart engineering.

Key Takeaways

- Linear actuators are essential in automation, transforming electric power into regulated straight-line displacement for precise applications.

- They enhance factory automation by providing reliability in assembly lines, robotic alignment, and flexible work surfaces.

- In healthcare, linear actuators improve equipment functionality and patient care by allowing for precise, smooth adjustments.

- The technology also finds applications in farming and nautical settings, enhancing productivity in remote environments.

- As smart frameworks evolve, linear actuators play a crucial role in connecting mechanical functions with electronic systems, ensuring efficiency and adaptability.

Table of contents

The Technical Basis for Regulated Straight-Line Displacement

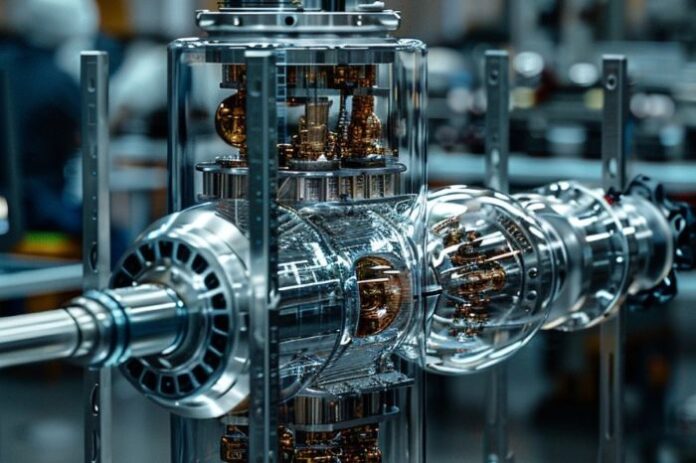

Within contemporary automation frameworks, linear motion actuators execute a straightforward physical function. They lengthen or shorten in a direct line to raise, angle, shift, or situate elements. This simple displacement gains strength when combined with scripted oversight systems and detectors.

Accurate alignment bolsters uniform results in assembly lines and robotic applications. Consistency guarantees that robotic limbs, surfaces, or bases revert to precise locations in every sequence. Electric linear motion actuators likewise merge smoothly with management panels, distant setups, and automated processes. Their space-saving build permits placement in tight areas where fluid cylinders prove unfeasible.

Producers like Progressive Automations supply electric linear actuators tailored for diverse weight limits and extension spans. This flexibility lets specialists align the actuator with the physical requirement instead of overhauling the whole framework around a displacement part.

The move to electrified displacement mirrors a wider sector inclination toward lessened upkeep intricacy and enhanced power conservation. Neat setup and basic cabling aid in optimized framework layout.

Production and Factory Automation

Factory settings require dependability. Assembly lines depend on coordinated displacement to sustain pace and item uniformity. Linear motion actuators frequently serve to modify transport setups, situate machining parts, and mechanize review processes.

In mechanized building, regulated lengthening and shortening can fix components securely prior to machine attachment. Flexible work surfaces enable comfortable alignment for workers or mechanized matching for equipment. Linear displacement aids these tasks with steady power and scripted scheduling.

Electrical setups additionally diminish the necessity for outside air pumps or fluid drivers. This streamlines upkeep timelines and reduces total setup area. As plants incorporate additional digital management tiers, electrical actuation blends effortlessly into connected settings.

Uses in factory automation commonly encompass

- Mechanized goods transport frameworks.

- Flexible assembly line elements.

- Robotic limb alignment.

- Regulated activation and deactivation systems.

- Exact elevation tuning in bundling machinery.

These instances underscore how straight-line displacement forms a core element in intricate mechanized frameworks.

Healthcare and Medical Device Advancement

Healthcare settings necessitate precision and silent functioning. Linear motion actuators aid flexible clinic beds, analysis tools, and operating surfaces where accurate alignment improves individual treatment.

Flexible therapy platforms permit experts to alter inclines fluidly. Scanning setups hinge on stable displacement to align imaging parts properly. Electric actuators deliver regulated displacement absent the shaking or liquid spills linked to dated fluid systems.

Protection ranks as a key factor in healthcare design. Electric linear actuators may feature boundary triggers and excess load safeguards to avert accidental displacement. This degree of inherent management aids in more secure and reactive medical tools.

Progressive Automations supplies actuator options crafted for trustworthiness in challenging settings. In healthcare scenarios, longevity and steady operation prove vital, especially where tools need to function repetitively all day.

Farming, Nautical, and Remote Uses

Outside factory and healthcare arenas, linear displacement tech assumes an increasing function in exterior and portable frameworks. In farming, actuators modify air flow panels in plant houses, manage supply portals, and mechanize watering systems. Regulated alignment boosts productivity while cutting hands-on work.

Nautical settings depend on electric actuators for cover management, chair modifications, and tool steadying. Space-saving build enables incorporation into restricted zones without major framework changes.

Remote and green power frameworks likewise gain from electric straight-line displacement. Sun panel groups can alter incline degrees during the day to maximize sunlight. Distant oversight paired with actuator management lets these frameworks react independently to surroundings.

Electrical actuation provides benefits in these settings as it lessens reliance on intricate fluid structures. This eases setup in isolated spots and aids modular framework layout.

Smart Frameworks and the Prospects of Straight-Line Displacement

As mechanization advances to intelligent production and linked tools, displacement parts must merge flawlessly with electronic networks. Linear motion actuators aid this advancement by linking physical displacement with scripted reasoning and detector input.

In robotics, actuators add to jointed displacement and regulated elevating. In intelligent furnishings and flexible building, they facilitate elevation-tunable workstations, shiftable dividers, and mechanized holding frameworks. These uses show how straight-line displacement stretches past robust sectors into routine smart engineering.

Merging with tiny controllers and IoT setups permits distant functioning and status tracking. Forward-looking upkeep turns feasible when displacement rounds and weight output get monitored electronically. This blend of physical trustworthiness and electronic supervision aids expandable progress.

Progressive Automations keeps supplying actuator tech that matches these changing needs. Through providing diverse strength levels and extension setups, their options aid uses spanning from factory mechanization to nascent intelligent frameworks.

Regulated straight-line displacement stays a basic component in contemporary design. Whether facilitating production accuracy, enhancing individual treatment tools, or aiding green power modifications, electric linear motion actuators deliver flexible, productive displacement. As sectors focus on mechanization, eco-friendliness, and smart merging, the function of linear actuation will keep growing across areas relying on dependable physical output.