The industrial landscape in the United States is undergoing a massive shift. As manufacturing repatriates and technology advances, owners of aging factories face a critical challenge: retrofitting decades-old facilities to meet modern operational and digital standards. According to a Forbes Tech Council analysis, 45% of manufacturers that have not yet adopted innovative technologies plan to do so within the next year, underscoring the urgency of modernization across the sector. However, many of these initiatives are constrained by facilities built long before today’s digital requirements.

These facilities are often labyrinths of structural steel and dense Mechanical, Electrical, and Plumbing (MEP) systems added incrementally over the last fifty years. In such environments, outdated drawings, undocumented modifications, and spatial congestion make renovation efforts highly risky. Renovating without accurate existing-conditions data quickly becomes a financial minefield, making the transition from laser scanning to precise 3D modeling not just beneficial, but essential.

This article explores a challenging Scan-to-BIM project undertaken by ViBIM for a manufacturing facility in the United States. It examines the complexities of modeling ultra-dense MEP systems from point cloud data. It demonstrates how specialized 3D BIM modeling services can convert chaotic reality-capture data into clean, coordinated, and actionable Revit models that support informed retrofit decision-making.

Table of contents

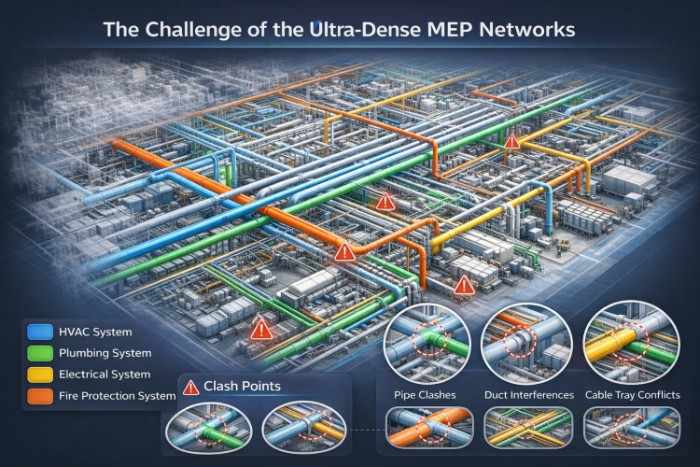

The Challenge of the Ultra-Dense MEP Networks

In industrial retrofits, the structural shell is rarely the problem. The primary adversary is the existing MEP infrastructure. In many U.S. factories, teams have installed, modified, and abandoned piping, ductwork, and conduit runs over time without updating documentation.

When a new line needs to be run or a new piece of equipment installed, relying on 2D legacy drawings often leads to catastrophic clashes during construction, making 3D BIM modeling services essential for accurately capturing existing conditions and coordinating new installations before work begins.

A clash discovered on-site requires work stoppages, material waste, and expensive change orders. To mitigate this risk, the industry has turned to High-Definition Surveying (HDS), or laser scanning, to capture the “as-is” conditions with millimeter accuracy. However, the resulting point cloud is simply a dense collection of data points. Professional point cloud to BIM services are essential for transforming raw data into intelligent Revit models. This conversion enables engineers to visualize potential conflicts, such as a steam pipe obstructing a proposed walkway, well before construction begins, turning static data into actionable insights.

Case Study: Revit Modeling for a US Factory with Dense MEP Systems

To understand the complexity of this process, we can look at a recent example involving the digitization of a manufacturing facility in the United States. The project scope was all-encompassing. ViBIM was tasked with converting raw point cloud data into a fully integrated Revit model that included:

- Comprehensive MEP Modeling: Create a detailed digital representation of all systems, including HVAC, Plumbing, Fire Fighting, Electrical, and Communication networks.

- Accurate Equipment Classification: Precisely classify and model major M&E equipment, ensuring every Revit component embeds correct technical specifications and asset data.

- Connected As-Built Model: Develop a fully connected digital model with logically linked systems that accurately reflect on-site conditions and adhere to strict technical standards.

The target for this digital asset was a Level of Development (LOD) 300, meaning the model elements needed to be graphically accurate in terms of quantity, size, shape, location, and orientation. The timeline was tight, with execution scheduled over two months.

Challenges

Modeling the dense MEP systems from point cloud data, particularly within a freshwater treatment machine room, presented a unique set of technical challenges:

- Extreme Density: The machine room was packed with a vast network of pipes and sensors, creating an overlapping point cloud that made isolating components difficult.

- Degraded Data Quality: High humidity and reflective surfaces impacted the laser scans, introducing noise and gaps that required meticulous cleanup.

- Object Differentiation: Distinguishing between similar objects, such as pipes and conduits, was difficult due to the high scan density and required expert interpretation.

- Strict Precision: The project demanded high accuracy; even minor positioning errors could cause critical clashes during future renovations.

- Lack of Non-Geometric Data: Since scans only capture geometry, our team had to source manually and embed non-graphical data, such as manufacturer specs and capacity.

- Large-Scale Data Management: The sheer volume of point cloud data requires a IT infrastructure to handle processing without performance delays.

Our Solutions and Approach

To address the extreme density and technical complexity of the freshwater treatment machine room, ViBIM implemented a standardized workflow supported by strict quality control. The team adopted a modular modeling approach, dividing the highly complex environment into smaller, manageable zones. Each zone was modeled independently before being fully integrated into the master model.

This strategy simplified coordination and allowed for continuous clash detection in Navisworks throughout the modeling process. As a result, MEP system conflicts were identified and resolved early. To ensure accuracy, the final BIM model was overlaid with the original point cloud data. Geometric fidelity was carefully verified before project delivery.

Supporting this workflow was a robust combination of enhanced team capabilities and resource management. We assigned a dedicated team of highly skilled professionals to meet the project’s demanding schedule. This ensured sufficient expertise and resources were available at every stage. The team received specialized training in advanced Scan-to-BIM point-cloud processing and complex MEP modeling. Their work was supported by high-performance hardware capable of handling large datasets without performance delays.

In addition, a centralized, server-based data management system was used to ensure secure storage and strict version control. This approach maintained a consistent information flow and alignment among all team members throughout the Scan-to-BIM project lifecycle.

How ViBIM’s 3D BIM Modeling Services Deliver Tangible Value to Your Facility

Transforming complex point cloud data into an intelligent Revit model creates a unified source of truth that delivers distinct, strategic value to Facility Owners, Contractors, and Facility Managers alike.

For Owners, the accurate as-built model serves as a foundation for comprehensive master planning. It allows stakeholders to assess the condition and viability of existing infrastructure accurately. This helps maximize the reuse of valuable assets and reduces unnecessary replacement. The model also enables precise visualization of how new machinery and production lines will integrate within the existing facility. This level of foresight gives teams greater control over the entire project lifecycle.

This proactive approach helps eliminate costly demolition, rework, and schedule delays. By resolving design conflicts during the digital planning phase, clients can avoid many of the unforeseen expenses commonly caused by change orders and on-site modifications. Over the building’s lifecycle, this leads to more predictable costs and smoother project execution.

For long-term operations, the BIM model functions as a comprehensive asset management database. It embeds detailed technical specifications and maintenance history for every MEP component, enabling streamlined tracking and proactive maintenance scheduling. This precision allows maintenance staff to quickly locate specific equipment within congested, hard-to-reach spaces, drastically improving safety and operational efficiency during inspections and repairs.

Are you facing challenges with a complex Scan-to-BIM project? Contact ViBIM today to learn how our specialized 3D BIM modeling services can streamline your workflow.