Over the last decade, enterprise digitalization has accelerated faster than any previous technological shift. Companies across manufacturing, construction, logistics, real estate, and energy production are migrating large portions of their operations into digital environments, no longer as a matter of convenience, but as a fundamental requirement for remaining competitive.

According to McKinsey, organizations that integrate data-rich digital twins into their workflows experience up to 35% faster decision-making, 20–30% reductions in operating costs, and notably higher asset reliability. This shift confirms a clear message: digital twins have evolved from experimental concepts into essential infrastructure. At the core of every precise and functional digital twin is one enabling technology: high-precision 3D scanning. Today, advanced spatial capture is not simply a tool but the foundation of operational intelligence.

Key Takeaways

- Digital Twins have become essential as industries face challenges like aging infrastructure and high maintenance costs.

- High-precision 3D scanning underpins Digital Twins, providing accurate data for simulations and decision-making.

- Organizations leveraging Digital Twins see improved efficiency, reduced costs, and enhanced collaboration across teams.

- Real-time operational twins represent the next evolution, utilizing live data to optimize performance and maintenance.

- Accurate 3D scanning ensures reliable Digital Twins, crucial for enterprises aiming to remain competitive through 2030.

Table of Contents

- Why Digital Twins Became Essential in 2026

- How Modern 3D Scanning Enables High-Value Digital Twins

- Industry Use Cases: Where Digital Twins Deliver the Highest ROI

- Why 3D Scanning Accuracy Matters More Than Ever

- The Rise of Real-Time Twins: The Next Stage of Digital Transformation

- Challenges Companies Face When Implementing Digital Twins

- What the Future Looks Like

- Final Thoughts

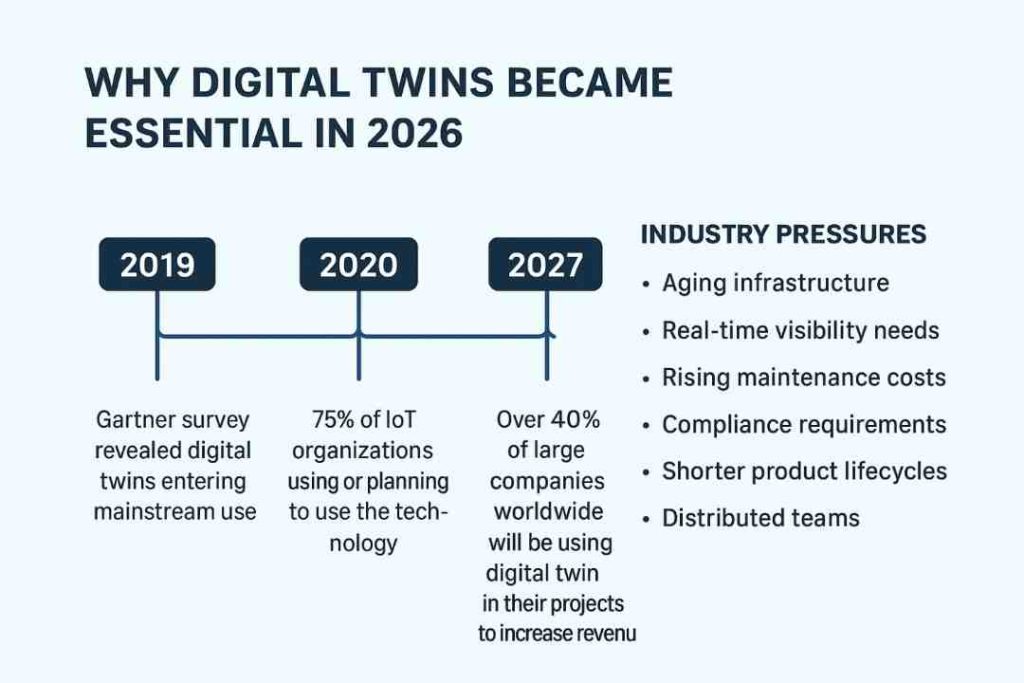

Why Digital Twins Became Essential in 2026

Most industries are now facing similar pressures, including aging infrastructure, undocumented assets, increasing demand for real-time project visibility, rising maintenance costs, stringent safety and compliance requirements, shorter product lifecycles, and the need for distributed teams to collaborate using accurate digital data. A digital twin addresses these challenges by providing a live, data-driven replica of a building, facility, asset, machine, or even a complete industrial system. However, to ensure that a digital twin is genuinely useful, it must be rooted in accurate data. This is where modern 3D scanning becomes indispensable, providing millimeter-level precision for reliable simulations, continuous monitoring, and automated decision-making. As a result, high-accuracy spatial scanning has emerged as one of the fastest and most effective pathways for enterprises entering the digital twin ecosystem.

This rise in adoption was already visible years earlier. In 2019, a Gartner survey revealed that Digital Twins were entering mainstream use, with 75% of IoT organizations using or planning to use the technology by 2020. Gartner further estimated that by 2027, more than 40 percent of large companies globally would adopt Digital Twin technology to increase revenue.

How Modern 3D Scanning Enables High-Value Digital Twins

1. Accurate Geometric Foundation

Digital twins require extremely detailed geometric data to support simulations, measurements, clash detection, and predictive maintenance. LiDAR-based scanning technologies now capture millions of points per second, generating data with ±2 mm accuracy. This level of detail ensures the resulting model is suitable for both engineering and operational use cases, eliminating guesswork and enhancing reliability.

2. Rapid Reality Capture for Large Assets

Unlike traditional surveying methods, which can take weeks, modern 3D scanning captures entire buildings, industrial equipment, and infrastructure systems within hours. This speed makes it economically feasible to deploy digital twins across large facilities or multiple assets in an enterprise portfolio, reducing labor requirements and accelerating project timelines.

3. Integration With BIM, IoT, and Automation

In 2026, digital twins commonly integrate BIM models, IoT sensor data, real-time operational inputs, predictive algorithms, and facility management systems. High-quality 3D scans provide the geometric accuracy needed for these components to align seamlessly. With reliably captured spatial data, enterprises can create a cohesive digital environment where all tools work together.

4. Lifecycle Optimization

Organizations leveraging digital twins supported by 3D scanning can simulate equipment failures before they occur, optimize energy consumption, reduce maintenance hours, automate asset tracking, analyze space utilization, and plan renovations with precise measurements. For manufacturing environments, this approach can reduce downtime by 15–40%, significantly improving operational efficiency.

Industry Use Cases: Where Digital Twins Deliver the Highest ROI

Manufacturing & Industrial Facilities

Factories are increasingly adopting digital twins to monitor production lines, analyze equipment movements, and enhance equipment layout planning. High-resolution scanning provides a complete 3D snapshot of conveyors, robotics, ducting, and support systems, enabling teams to streamline upgrades and reduce downtime associated with major facility changes.

Construction & Real Estate Development

Developers are using digital twins to manage entire building lifecycles from conceptual design and BIM coordination to handover and ongoing maintenance. This approach reduces RFIs, eliminates costly rework, and accelerates construction schedules by providing accurate and unified data throughout every project stage.

Energy, Utilities, and Infrastructure

Companies in oil and gas, renewable energy, telecommunications, and utilities use digital twins for remote inspections, compliance documentation, maintenance planning, and large-scale modernization efforts. With 3D scanning, these tasks can be completed with fewer on-site crew deployments, reducing risk and operational costs.

Healthcare & Research Facilities

Hospitals and laboratories rely on digital twins for equipment planning, airflow simulation, safety assessment, and patient-flow optimization. In these environments, where spatial errors can cost millions or jeopardize safety, high-accuracy scanning ensures that every decision is based on reliable information.

Why 3D Scanning Accuracy Matters More Than Ever

A digital twin’s value depends entirely on the accuracy of its underlying data. Low-quality scans can lead to flawed simulations, incorrect measurements, BIM inconsistencies, MEP coordination problems, and unreliable maintenance planning. For this reason, organizations now depend on specialized providers who use LiDAR, photogrammetry, SLAM, and machine-learning–assisted reconstruction to achieve the highest levels of precision. If you’re seeking a vetted professional capable of creating accurate digital twins and as-built models, consider this resource: 👉 3D scanning company in the USA.

The Rise of Real-Time Twins: The Next Stage of Digital Transformation

While static digital twins have become mainstream, the next major evolution lies in real-time operational twins. These advanced systems rely on IoT sensors that stream live data, AI models that predict failures, and automated systems that adjust facility conditions in real time. For digital twins to operate at this level, organizations must maintain centimeter-accurate geometry, perfectly aligned BIM models, consistent field updates, and regularly scheduled or on-demand high-resolution 3D scans. Enterprises adopting this approach often achieve 25–50% reductions in maintenance costs, significantly faster facility planning cycles, and substantial improvements in compliance and safety across operations.

Challenges Companies Face When Implementing Digital Twins

Despite their advantages, digital twins can fail when they are built on inaccurate geometry, when frequent site updates are neglected, when IoT data fails to synchronize correctly, when BIM standards are inconsistent, or when team workflows are fragmented. The most effective way to avoid these issues is to base the digital twin on verified, high-accuracy 3D scans combined with clear modeling standards and structured data governance.

What the Future Looks Like

By 2030, more than 70% of major enterprises are projected to implement full digital twins for their most valuable assets. Growth is expected across a wide range of sectors, including industrial robotics, smart factories, energy systems, transportation networks, healthcare facilities, public safety infrastructure, and emergency-response planning. Across all these areas, 3D scanning will remain the reality-capture engine that keeps digital twins accurate, dynamic, and operational.

Final Thoughts

Digital twins have rapidly evolved from emerging concepts into the operational backbone of modern American enterprises. As organizations continue shifting toward real-time analytics, automation, and data-driven decision-making, those that develop accurate, high-fidelity digital replicas of their assets will set the performance standard for the next decade. The path forward is clear: businesses that invest early in precision 3D capture and digital-twin infrastructure will secure a measurable competitive advantage in 2026 and beyond.