A practical guide for distributors and OEMs on using blockchain for chip provenance to authenticate semiconductor parts and reduce supply delays.

Key Takeaways

- Counterfeit semiconductors can cause major supply chain disruptions, making chip provenance crucial.

- Blockchain can enhance chip provenance by creating an immutable digital ledger of a chip’s journey, ensuring authenticity.

- Implementing blockchain involves steps like creating unique digital identifiers, logging transactions, and automating processes with smart contracts.

- Benefits of using blockchain for chip provenance include faster verification, reduced counterfeit risks, and improved buyer confidence.

- Challenges exist, such as ensuring physical security and the initial costs of implementation, but these can be managed with a thoughtful approach.

Table of Contents

- Why Provenance Matters Now More Than Ever

- The Problem: Counterfeits, Delays, and the Business Impact

- Blockchain 101: A Practical Explainer for Supply Chains

- How Blockchain Maps to Chip Provenance: A Step-by-Step Guide

- Practical Implementation Roadmap: An Actionable Checklist

- Benefits and Limitations: A Balanced View

- A Quick Illustrative Example

- Conclusion: A Practical Step Toward Trust

- FAQs

Why Provenance Matters Now More Than Ever

For any business in industrial automation, a counterfeit semiconductor isn’t just a faulty part; it’s a catalyst for catastrophic failure. Production halts and compromises safety systems. Urgent investigations burn through time and money. While no single technology is a magic bullet, blockchain offers a powerful new layer of defense. It enables verifiable chip provenance. This article provides a practical primer on how a distributed ledger can secure the component supply chain. It includes an implementation checklist and answers to common questions.

The Problem: Counterfeits, Delays, and the Business Impact

The electronic component supply chain is rife with vulnerabilities that bad actors exploit daily. These issues typically manifest in a few common ways:

- Counterfeit or Remanufactured Parts: Fake components, or used parts remarked and sold as new, enter the supply stream. They often come with performance or reliability defects.

- Diverted Inventory: Genuine parts intended for one market or customer are illicitly rerouted. This creates grey markets that lack traceability and support.

- Incomplete or Falsified Paperwork: Paper-based certificates of conformity and invoices are easily forged, making manual verification slow and unreliable.

The consequences are severe, extending far beyond the cost of a single bad part. Businesses face unplanned production downtime, increased warranty claims, and significant safety risks. Furthermore, navigating regulatory non-compliance and bearing the high costs of forensic inspection erodes both profits and customer trust. Traditional methods of verification—spot testing, paper trails, and supplier audits—are too manual. They are too slow and easy to circumvent in today’s fast-moving global market.

Blockchain 101: A Practical Explainer for Supply Chains

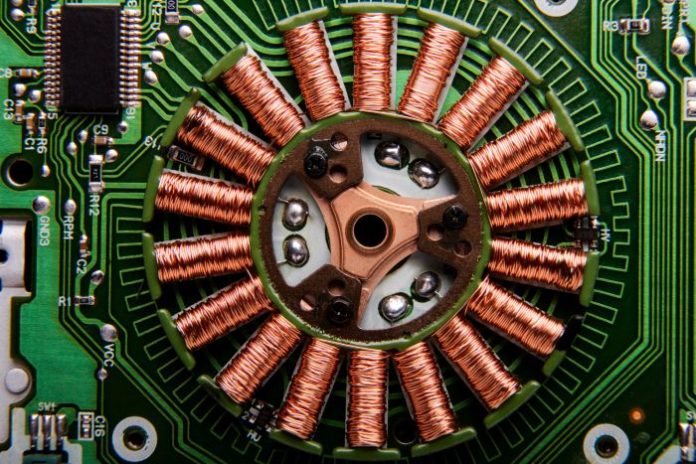

At its core, a blockchain is simply an immutable, time-stamped digital ledger where a distributed network of computers records and verifies transactions. Think of it as a shared, unchangeable logbook. For industrial supply chains, the most relevant type is a permissioned or consortium blockchain. In this type, only authorized partners (manufacturers, distributors, OEMs) can participate. This ensures privacy and control.

Crucially, the blockchain doesn’t magically verify a physical chip; it verifies the digital record of its journey. It proves the chain of custody and associated metadata. Therefore, blockchain must be paired with secure physical tagging. This links the physical asset to its digital twin on the ledger.

“Blockchain reduces investigation time; it’s not a replacement for physical security, but a powerful complement to it.”

How Blockchain Maps to Chip Provenance: A Step-by-Step Guide

So, how does this digital ledger actually stop a fake chip and speed up logistics? The process creates a verifiable, end-to-end audit trail.

- Create a Unique Digital Birth Certificate: At the point of manufacture, each chip or batch is assigned a unique identifier. This could be a physically unclonable function (PUF), a cryptographically secured serial number, or an encrypted NFC/RFID tag that is difficult to clone.

- Log Each Touchpoint on the Ledger: As the component moves from the manufacturer to the distributor, through logistics, and finally to the OEM or assembler, each handoff is recorded. It is noted as a digitally signed transaction on the blockchain. This entry includes who handled it, when, and where. This is essential for everything from simple relays to the complex controllers found in ChipsGate PLCs and controllers.

- Build an Immutable Audit Trail: This sequence of transactions creates a tamper-proof history. Any mismatch, like a part showing up in a location it shouldn’t be, instantly flags a potential issue. A gap in its custody chain allows for rapid quarantine and investigation.

- Automate Processes with Smart Contracts: Code can be built into the ledger to automate actions. For example, a smart contract could automatically release payment to a distributor. This happens once an OEM’s system verifies the provenance of a received shipment, or places a hold on a batch if a scan reveals an anomaly.

This system transforms investigations from a weeks-long process of chasing paperwork and performing costly lab tests into a near-instant digital check.

Practical Implementation Roadmap: An Actionable Checklist

Starting a blockchain provenance project may seem daunting, but you can approach it systematically.

- Define a Narrow Scope: Start small. Select a single high-risk SKU or part family, one trusted supplier, and a clear geographic boundary for your pilot project.

- Choose the Right Ledger: For most industrial uses, a permissioned blockchain like Hyperledger Fabric or R3 Corda is ideal. Alternatively, managed Blockchain-as-a-Service (BaaS) platforms can lower the barrier to entry.

- Select a Physical Binding Method: The digital record is only as good as its link to the physical part. Choose a method appropriate for your component, such as a secure QR code, a laser-etched serial, or a tamper-evident RFID/NFC tag.

- Integrate Key Systems: Your blockchain needs to talk to your existing ERP and Warehouse Management Systems (WMS). Develop APIs to allow buyers and internal teams to easily query the ledger for provenance data.

- Run a Pilot (3-6 Months): Test the system with your chosen scope. The goal is to prove the technology, workflow, and business value before scaling.

- Track Clear KPIs: Measure success with metrics like chip provenance data coverage (%), counterfeit detection time, dispute resolution time, and reduction in customer returns due to authenticity claims.

- Establish Data Governance: Partner with stakeholders to define who can write data to the ledger, what information is shared, and how the system meets privacy and industry regulations.

Benefits and Limitations: A Balanced View

Adopting blockchain is a strategic decision with clear trade-offs.

Key Benefits

- Drastically Faster Verification: Reduce provenance investigation time from weeks to mere minutes.

- Reduced Counterfeit Incursions: Raise the cost and complexity for counterfeiters, making your supply chain a harder target.

- Enhanced Buyer Confidence: Provide customers with a simple, verifiable way to confirm they are receiving genuine parts.

- Streamlined Recalls & Audits: Quickly identify the location and history of every part in a specific batch, simplifying compliance and recalls.

- Potential for Lower Insurance Premiums: A demonstrably secure supply chain can lead to advantages with insurers and partners.

Limitations and Caveats

- “Garbage In, Garbage Out”: The blockchain cannot know if a fake part was added at the source. It only guarantees that the recorded information is immutable.

- Physical Security is Paramount: If the physical tag (e.g., a simple QR code) can be easily cloned, the system’s integrity is compromised.

- Initial Cost & Complexity: Implementation requires investment in technology, system integration, and partner onboarding.

- The Network Effect: The system delivers maximum value when all partners in the supply chain participate. Early adopters may have a limited impact until they reach a critical mass.

Using strong, hardware-based physical tags, allowing only trusted foundries to write the initial ‘birth certificate’ data, and conducting regular third-party audits can mitigate these limitations.

A Quick Illustrative Example

An industrial automation OEM receives a shipment of high-value microcontrollers. During incoming inspection, a technician scans a sample of parts. The blockchain ledger immediately flags one reel as having a distributor record that doesn’t match the authorized channel. By holding the entire shipment, the OEM averts a production crisis and saves an estimated two weeks of potential downtime that would otherwise go toward reactive failure analysis.

Conclusion: A Practical Step Toward Trust

Blockchain is not a cure-all, but it is one of the most effective tools available today for securing the electronics supply chain. By creating a transparent, immutable, and easily auditable record of a component’s journey, it fundamentally raises the bar for counterfeiters and shortens the time it takes to resolve costly disputes. For procurement managers and engineers tired of fighting a reactive battle against fakes and delays, it represents a practical, measurable step toward building a more resilient and trustworthy supply chain.

Ready to explore how a secured supply chain can benefit your operations? The experts at ChipsGate can help you assess your needs, from sourcing authentic ChipsGate IC chips to designing a pilot program for chip provenance.

FAQs

No. It immutably guarantees the recorded chain of custody. To ensure authenticity, a trusted source, such as the original component manufacturer, must combine it with secure physical tags.

Permissioned ledgers like Hyperledger Fabric or R3 Corda are the industry standard. They offer the necessary control, privacy, and performance for B2B supply chains. Choosing depends on your specific governance and scalability needs.

Yes. The cost of entry has fallen significantly. Small businesses can start with focused pilots, join industry consortia to share costs, or use third-party provenance-as-a-service providers to avoid large upfront investments.

You can see an immediate drop in detection and response time. However, a systemic reduction in the number of counterfeit attempts depends on broader supplier adoption, which can take several months to years to achieve across the industry.