The new energy vehicles (NEVs) boom has piled pressure on manufacturers to produce vehicles with a record degree of accuracy, as well as scale. To satisfy these requirements, industry players are increasingly relying on AI-driven fiber laser systems over traditional hardware; they serve as the intelligent foundations that underpin the new production process.

Unlike traditional machining, which often struggles with micron-level tolerances or dynamic material conditions, intelligent laser systems combine fiber laser hardware with real-time software intelligence. In fact, recent studies indicate how AI integration can reduce prediction errors in welding deformation to as little as 0.75 mm using deep neural networks and 0.85 mm with convolutional neural networks—demonstrating a tangible leap in precision and control. This convergence is not just improving part quality; it is redefining how factories operate.

Table of contents

- Intelligent Laser Automation: Not Just Faster Smarter

- Case Example: AI in High-Speed Battery Pole Cutting

- Digital Twins & Real-Time Monitoring

- Expert Insight: The Factory That Thinks

- Software-Driven Innovation in laser cutting and welding selection

- Rewriting the Blueprint: From Equipment to Smart Assets

- Final Thoughts: Lasers Reinvented by Software

Intelligent Laser Automation: Not Just Faster Smarter

AI-enhanced fiber laser cutting systems are shifting the goalposts. According to recent case reports, these systems have reduced processing times by 25% compared to manual setups, while also achieving 40% greater energy efficiency thanks to adaptive software adjustments that optimize power, speed, and beam focus in real time.

In EV battery production, where companies like CATL and BYD have ramped up their output, AI-enhanced laser systems now deliver cuts in under 6 seconds, with automated calibration significantly reducing scrap rates. When combined with MES (Manufacturing Execution Systems), these systems form closed-loop feedback loops that continuously self-optimize.

Related resource: Top 10 Best Laser Welding Machine Manufacturers

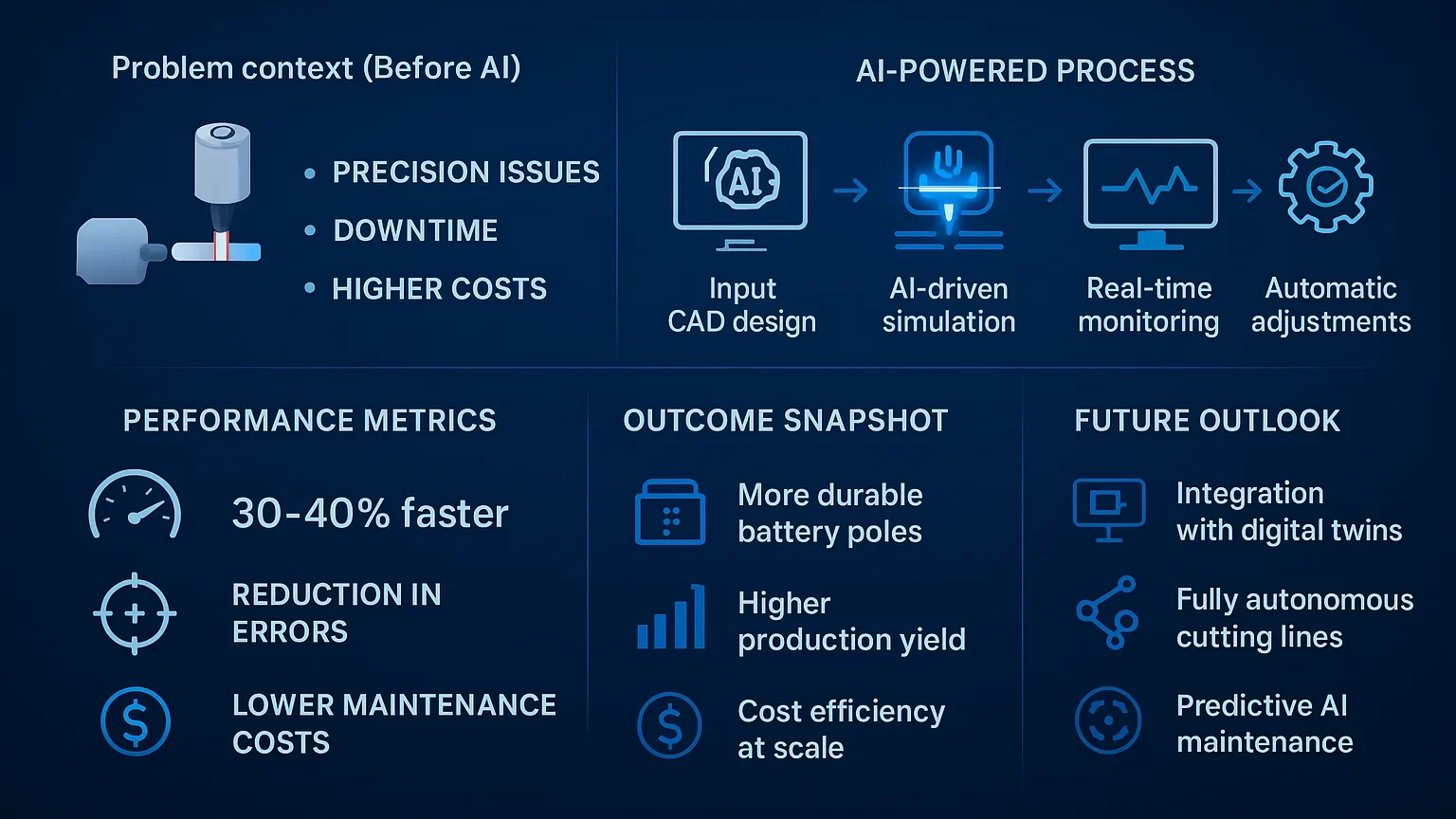

Case Example: AI in High-Speed Battery Pole Cutting

With EV battery pole production volumes increasing by over 150% in recent years, manufacturers such as CATL and BYD have deployed AI-enhanced fiber laser systems on a large scale. These systems utilize machine vision and real-time feedback to maintain cycle times, dynamically adjust parameters, and minimize scrap.

By leveraging data from previous cuts and integrating with upstream MES systems, these bright lasers create feedback that improves with every cycle.

Digital Twins & Real-Time Monitoring

Recent research is emphasizing the importance of digital twins and data-based machine learning in laser processing. These digital twins enable manufacturers to simulate, optimize, and predict outcomes before initiating physical production, thereby reducing defects and enhancing control.

A recent multimodal monitoring framework, combining acoustic and visual sensing with AI algorithms, achieved 94.4% accuracy in detecting geometric defects in additive manufacturing, marking a breakthrough in ensuring laser precision at scale.

Expert Insight: The Factory That Thinks

Manufacturing futurists are weighing in with bold visions. At the 2025 Reagan Library Economic Forum, venture capitalist Marc Andreessen described the future of U.S. manufacturing as one fueled by “alien dreadnought factories,” hyper-automated, AI-enabled facilities built to outpace global competition. He emphasized that software innovation, particularly robotics and automation, will be the defining edge in industrial leadership.

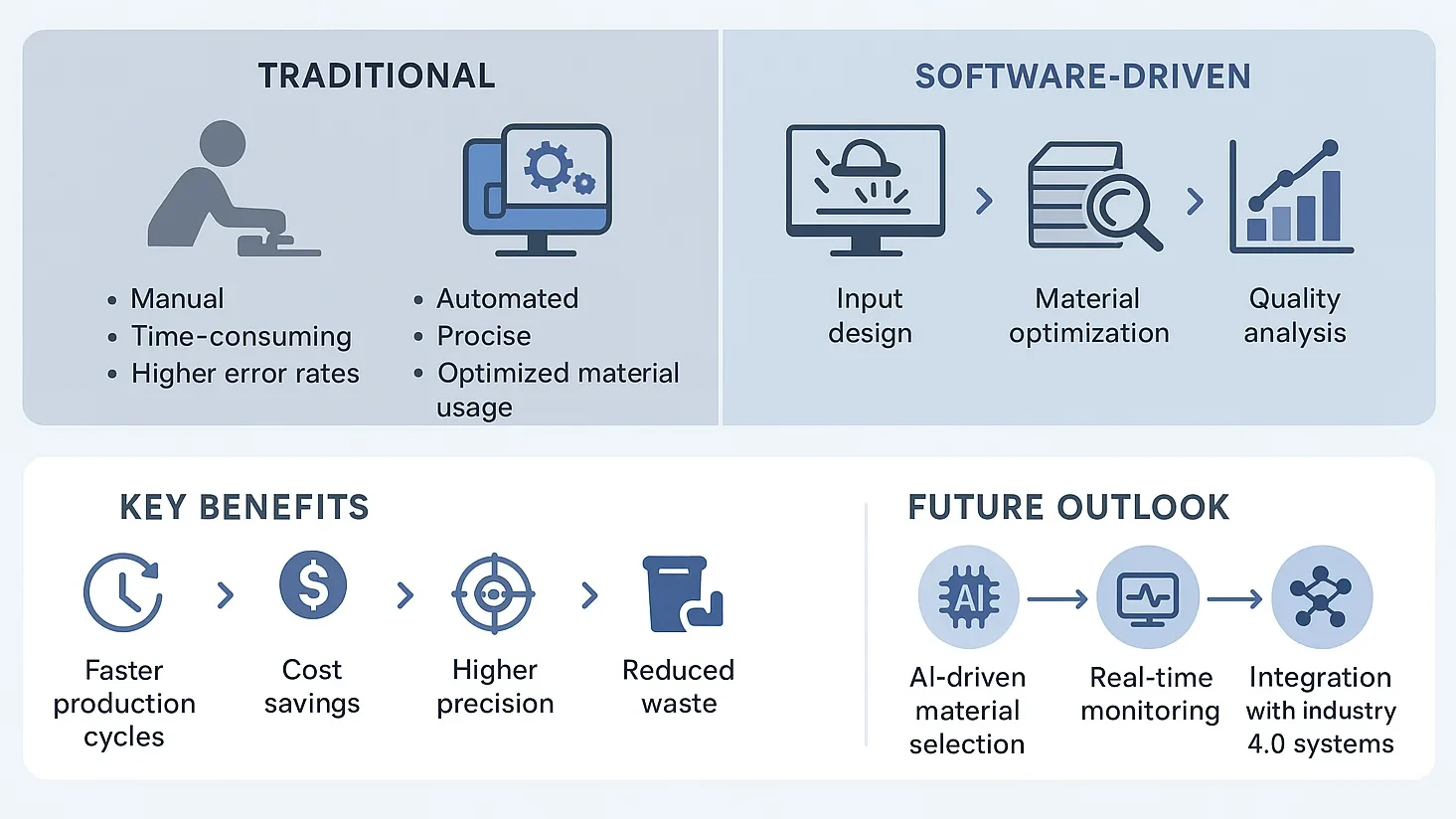

Software-Driven Innovation in laser cutting and welding selection

Today, laser cutting and welding selection is no longer just about speed or heat control; it is a software-centric decision. Manufacturers evaluate laser platforms based on their AI capabilities, system integration, and data traceability.

Below is a simplified table illustrating the software-driven benefits of laser cutting and welding selection:

| Feature | Software Enhancement | Benefit to EV Manufacturing |

| AI-Driven Speed Control | Adjusts parameters based on material feedback | Ensures fast and accurate cuts/welds |

| Real-Time Quality Checks | Uses sensors and feedback loops | Reduces scrap and improves precision |

| Material Flexibility | Stores presets for multiple material types | Enables faster transitions and lower downtime |

| Data Integration | Syncs with MES/ERP platforms | Enables traceability and regulatory compliance |

| Predictive Maintenance | Analyzes machine usage patterns | Prevents failures and extends equipment lifespan |

One automation strategist at a leading EV manufacturer remarked, “Fiber lasers powered by machine learning aren’t just cutting parts faster. They’re training the factory to think smarter.”

Rewriting the Blueprint: From Equipment to Smart Assets

Fiber lasers today aren’t just isolated tools; they’re part of an AI-rich ecosystem that connects with ERP, MES, IIoT, and even cloud analytics. This connectivity enables tracing, predictive maintenance, and real-time monitoring, providing the plant manager with complete visibility of all operations. The result is a productive, responsive factory that was designed for the long term.

Final Thoughts: Lasers Reinvented by Software

In the high-stakes race toward electrification, manufacturers embracing AI-powered laser platforms are gaining a clear edge. By treating these systems as cloud-connected, updatable software assets, companies can unlock faster cycle times, lower energy usage, and intelligent scalability.

The smart factory is here, and it’s powered by code.