Introduction

Rapid charging technologies have revolutionized the design of next-generation energy storage systems, such as lithium-ion batteries used in smartphones, laptops, and electric vehicles (EVs). Although these approaches do reduce charging times, they raise concerns such as heat and lithium plating, as well as accelerated aging. In response to these concerns, BMS has developed from rule-based controllers to AI-enabled optimization frameworks.

This paper examines the application of AI in BMS designs. It explores how AI can extend the lifespan of the battery, as well as recent research directions in this emerging and important field.

Table of contents

Lithium-Ion Battery Charging Challenges

Lithium-ion charging traditionally follows a constant current (CC) to constant voltage (CV) process. Fast charging accelerates the CC phase, pushing more ions into the anode in a shorter time. The main risks associated with this approach include:

- Thermal stress due to increased internal resistance and Joule heating.

- Lithium plating, where metallic lithium deposits form on the anode surface during aggressive charging

- Reduced cycle life, as accelerated side reactions degrade active material.

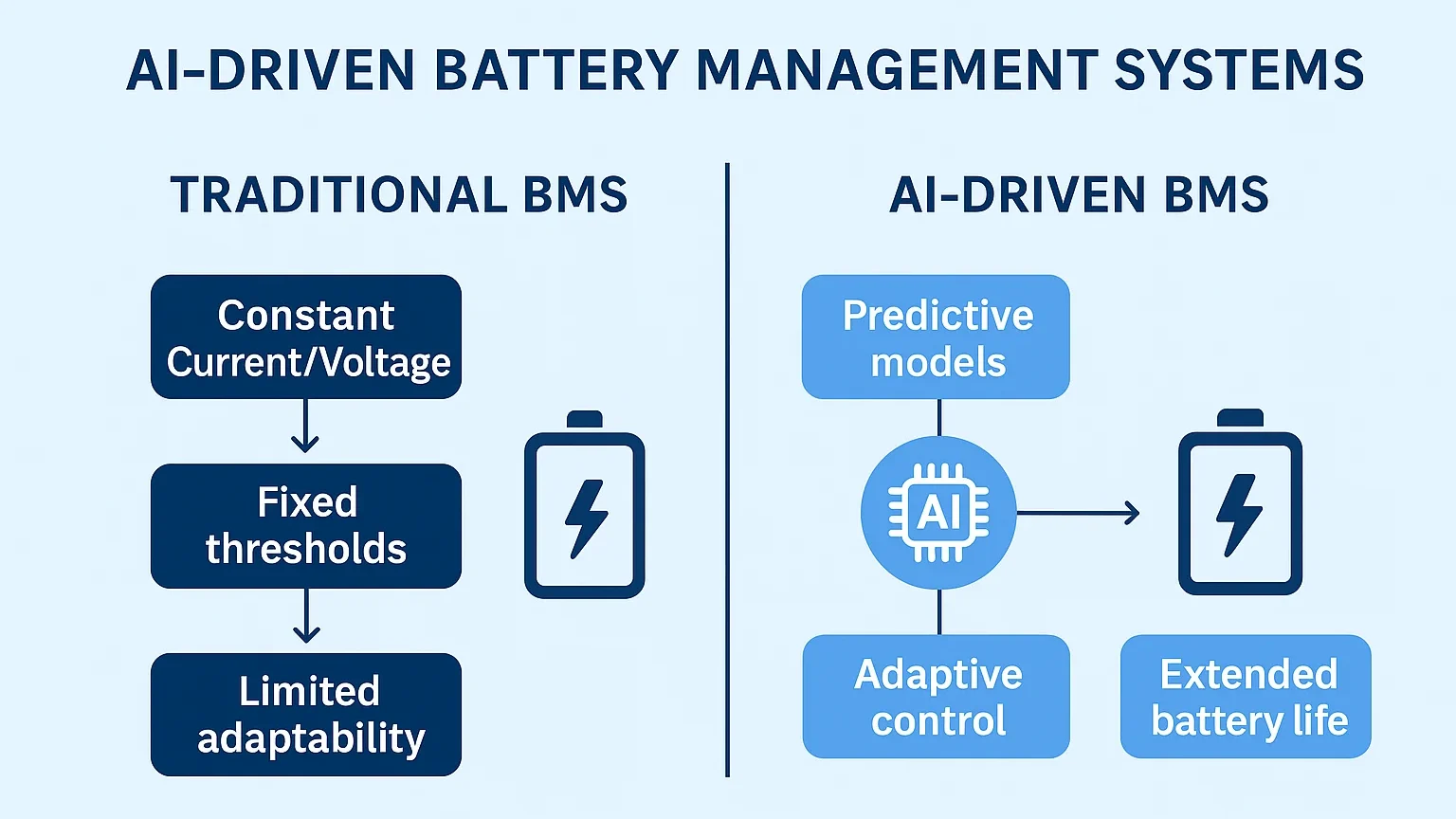

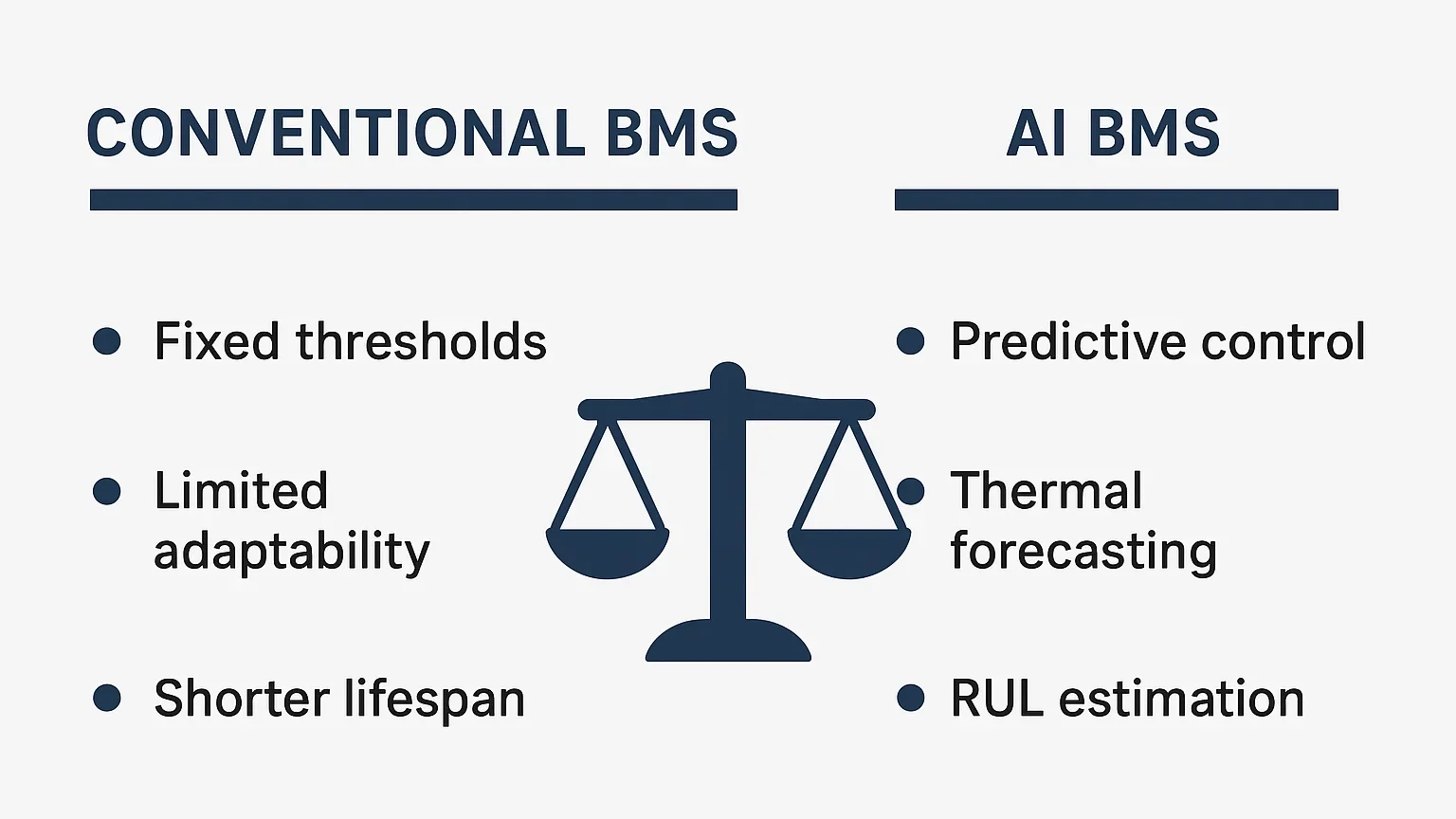

Traditional BMS solutions mitigate these effects using fixed thresholds for current, voltage, and temperature. However, these rule-based systems cannot adapt dynamically to battery chemistry variations, user behavior, or real-time environmental conditions.

AI in Battery Management: Core Approaches

Data-Driven Modeling

While physics-based electrochemical models were the norm, AI systems construct predictive models from historical and real-time operational data. Techniques, such as neural networks, support vector machines (SVMs), and Gaussian process regression, have also been used for predicting SoC, SoH, and thermal response.

Predictive Charging Control

Machine learning models predict how the battery will perform with various charging currents. This provides a triggering mechanism before the dangerous situation occurs. For instance, Kalman filters integrated with neural networks have been deployed to enhance the precision of SoC and SoH estimation beyond the implementation of conventional methods.

Reinforcement Learning for Adaptive Charging

By using RL, the BMS can “learn” best charging strategies through trial and error behaviour in a simulated environment. Through a trade-off between speed and degradation cost, RL agents can create charging profiles that increase the cycle life while ensuring user convenience.

Digital Twins and Real-Time Simulation

A digital twin is a replica of a battery cell or pack, in the virtual world, that mirrors what happens in the real world. By running AI-enhanced simulations alongside physical operation, the BMS can test charging strategies in the digital twin before deploying them for real, minimising risk.

AI-Based Thermal and Safety Management

Temperature is a critical factor in lithium battery health. AI models such as convolutional neural networks (CNNs) and long short-term memory (LSTM) networks have been employed to predict temperature rise under varying load conditions. By forecasting thermal behavior, the BMS can:

- Adjust charging current dynamically

- Activate cooling systems in EVs proactively

- Prevent hotspots that accelerate degradation.

This predictive capability improves safety and extends useful life without relying solely on conservative thresholds.

Remaining Useful Life (RUL) Estimation

RUL prediction stands out as the most noteworthy AI technique in the field of BMS, estimating the remaining charge-discharge cycles before the capacity drops below the usable limit. Research is demonstrating that hybrid systems combining EIS and ML methods are capable of generating very accurate degradation predictions. These observations allow preventive measures, including:

- Restricting aggressive charging when the battery nears the end of its life

- Suggesting optimal charging habits tailored to specific usage patterns

- Extending operational safety margins in EV fleets and grid storage systems.

For industries and every lithium battery manufacturer, the integration of AI-based BMS during design and production stages allows optimization not just at the system level, but also at the material and cell level. This ensures that new batteries are engineered to handle higher charging rates without compromising safety or lifespan.

Research Trends and Future Directions

1. Hybrid Physics: AI Models

Purely data-driven models may lack generalization in new conditions. Current research emphasizes physics-informed machine learning, which combines electrochemical equations with AI adaptability to achieve improved accuracy across various chemistries and environments.

2. Federated Learning for Distributed Batteries

With millions of EVs and consumer devices in use, federated learning enables BMS systems to collaborate without the need to centralize raw data, given the schedules of millions of EVs and consumer electronics. This enhances AI models while preserving data privacy.BMS systems to share insights without centralizing raw data. This enhances AI models while maintaining data privacy.

3. Reinforcement Learning for Grid Integration

It is understood that the charging of electric vehicles, as assets connected to smart grids, must be efficient and require demand-response. RL-based BMS approaches are being investigated that aim to balance battery health on an individual level and maintain grid stability.

4. Self-Healing Charging Strategies

AI is learning to identify micro-level degradation markers and adjust charging profiles in ways that slow or partially reverse the damaging effects, a field that’s still in its early experimentation stage.

Conclusion

AI-driven Battery Management Systems represent a paradigm shift in lithium-ion technology. By integrating predictive modeling, reinforcement learning, and digital twin simulations, these systems adapt to real-time conditions, extend cycle life, and enhance safety beyond what conventional rule-based systems can achieve.

Ongoing research is pushing toward hybrid electrochemical AI models, federated learning for distributed devices, and self-healing strategies. As these methods mature, AI-optimized BMS will make fast charging safer and transform battery maintenance across consumer electronics.